Returns Forecasting for Peak Season Readiness

Retailers can make a significant part of their yearly revenue during the holiday season, so it is common to see them investing heavily in forecasting sales as accurately as possible. To ensure that, they stock inventory, ramp up marketing efforts, and fine tune logistics to satisfy their customers. In that chaotic excitement, many forget about returns forecasting and the need to be prepared.

The idea is simple. In today’s market, any surge in sales will come with a corresponding surge in returns. So yes, you can do all the sales planning you want but the entire sales process will struggle if you do not plan the post-holiday returns with as much grit as the sales forecast. Warehouses will be overwhelmed, the supply chain can be strained, and then there is also the danger of customer frustration.

Returns forecasting turns the inevitable tide of returned merchandise into a manageable process, and equips the operations team, fulfillment team, and customer service team with the tools they need to process refunds quickly and maintain a seamless customer experience.

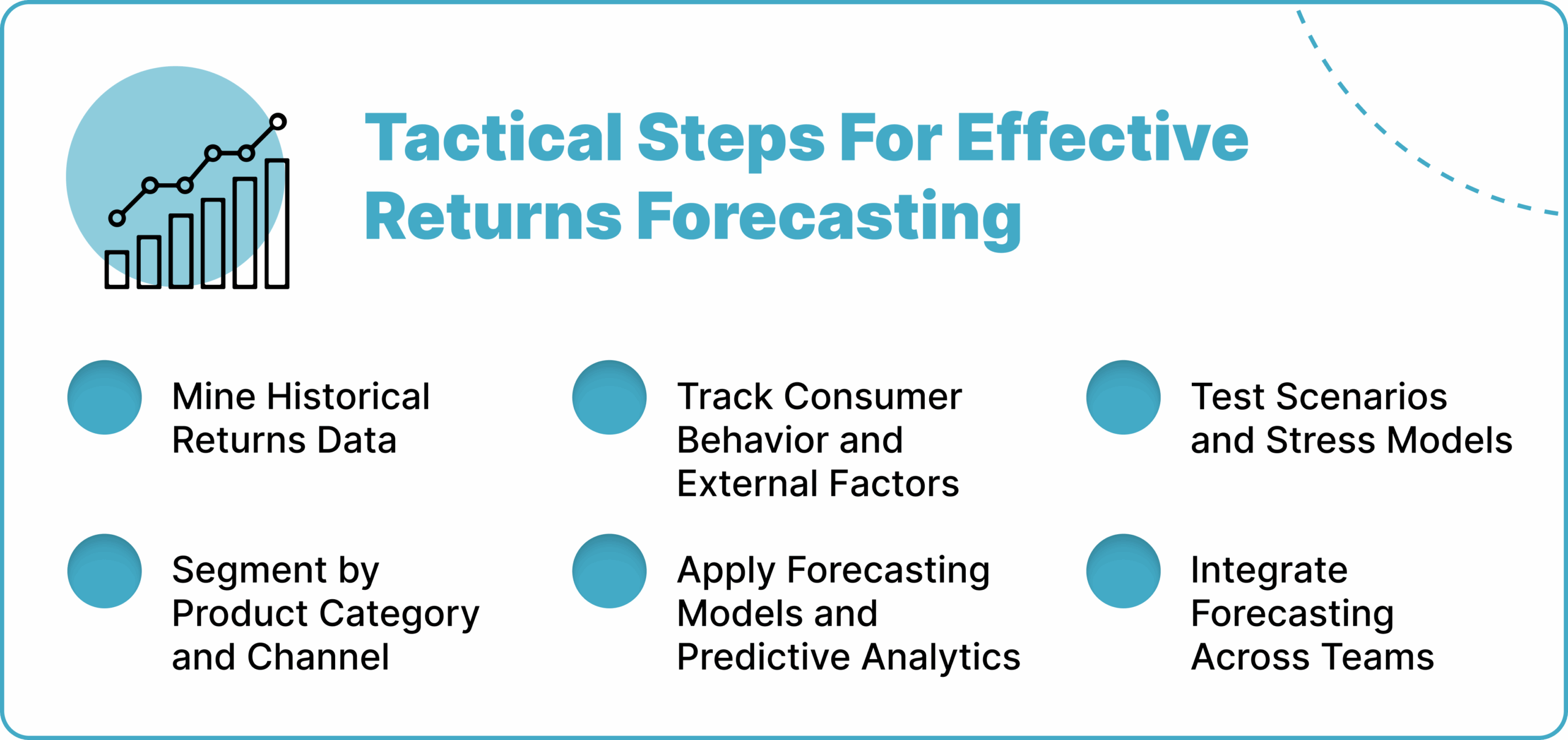

Tactical Steps For Effective Returns Forecasting

Accurate forecasting is the first step in managing holiday returns. And the retailers that expect rather than react can prevent chaos when the holiday is over. Here are some tactical steps to ensure effective returns forecasting:

1. Mine Historical Returns Data

Returns forecasting begins with the compilation of accurate historical data. And past holiday seasons can provide a baseline for seasonal returns. For example, apparel brands often see 25–30% of holiday purchases come back, while electronics average closer to 15%. Knowing these will guide you in making realistic estimates for future returns.

2. Segment by Product Category and Channel

Your forecasting accuracy will improve when returns are segmented. Take, for example, categories such as fashion, footwear, and electronics that consistently carry a higher likelihood of return. Additionally, e-commerce returns are often double those of in-store purchases, due to factors like bracketing and gift-buying behaviors. By segmenting potential returns by channels and categories, your operations teams can forecast returns with accuracy, which in turn allows you to allocate resources effectively.

3. Track Consumer Behavior and External Factors

Forecasting future returns requires awareness of consumer behavior. Given current trends — such as shoppers ordering multiple sizes or styles with the intention of returning some, and gift recipients frequently exchanging items that don’t suit their needs — many returns should come as no surprise.

Changes to the returns policy, such as extended holiday return windows, can alter the timing of reverse flows. And external factors, such as shipping delays or economic pressure, also impact return rates. By anticipating these factors, you can adjust the forecasts before bottlenecks emerge.

4. Apply Forecasting Models and Predictive Analytics

Returns forecasting improves with models that merge historical data and current data. For example, time series analysis and regression models can help project return rates across categories. Predictive analytics and machine learning refine forecasts by accounting for independent variables such as promotions, shipping delays, and regional buying patterns. By correctly applying these models, you can anticipate spikes in post-holiday returns, rather than scrambling after the new year begins.

5. Test Scenarios and Stress Models

Scenario planning exposes risks, and you can, for example, simulate the effect of offering free holiday returns or extending policies until February. While these policies may lift sales, they also have the potential to increase return volumes. A retailer that tests scenarios can prepare storage, staff, and refunds in advance. Stress testing ensures the system holds up when the unexpected happens such as returned items doubling or tripling in volume.

6. Integrate Forecasting Across Teams

Returns forecasts are only valuable when shared with other stakeholders in the reverse supply chain process. For instance:

- The operations team needs to know what type of items and the expected number to be returned each week in January so they can plan effectively.

- The fulfillment team must plan for space to store returned merchandise, otherwise it turns into a chaos.

- The customer service team requires visibility into expected refund volumes to staff accordingly and make sure customers are provided with reliable and accurate information.

Preparing Operations for the Return Surge

Returns forecasting is the foundation, but acting on the forecast is what prevents breakdowns in post-holiday returns management.

1. Warehouse Readiness and Capacity Planning

Returned merchandise requires space, and failing to plan for that will often result in congestion and delays. This is why capacity planning based on forecasted return rates is so essential in the returns management process.

For example, fast-moving returned items should have a dedicated space for inspection and restocking. Electronics may require separate zones for refurbishment, and non-saleable goods should have designated disposal areas to prevent contamination of saleable stock.

2. Staffing and Labor Planning

Labor shortages are common during peak season. By accurately forecasting these returns, retailers can determine the exact number of seasonal staff needed to focus on returns management and reverse logistics operations. The forecast also determines the level of training that should be set up to cover not only processing but also fraud detection, as fraudulent returns tend to peak after the holidays.

There are a few things to note, though. Staff should be trained to process refunds quickly because it gives customers confidence in the brand. Labor schedules should also align with forecasted peaks, typically the first two weeks after Christmas.

3. Reverse Logistics Workflows

Bottlenecks occur when the workflows are unclear. However, by standardizing returns management processes such as intake, inspection, and restocking, you can reduce errors in the returns process. To ensure that and speed up the processing, you can leverage a triage system where:

- Defective goods are moved to repair.

- Resalable goods are returned to stock.

- Unsalvageable items are removed from the system.

You can also automate the process with barcode scanning or AI sorting, which boosts operational efficiency. The faster your warehouse moves returned items, the faster refunds reach customers, which strengthens customer loyalty.

4. Technology and Visibility

Today, customers expect real-time tracking of their return items and refunds. This is why returns management software such as ReverseLogix is vital during the post-holiday spikes. ReverseLogix, for example, connects forecasting, warehouse operations, and customer-facing systems, providing consolidated insights on one single dashboard. Now, you have a system that provides updates, reduces the need for customer service calls, and improves overall customer experience. With the solution, you also have access to insights comparing forecasted versus actual returns, enabling the team to adjust resources on a daily basis.

5. Carrier and Logistics Coordination

Reverse logistics put strain on carriers, especially during and after the holiday season. This is why it is necessary that you work closely with carriers to prepare ahead for the holiday return season.

For example, pre-booking capacity in early January helps prevent delays and regional surges, such as those in gift-heavy urban areas, which require diversified carriers. Coordinating return shipping is just as important as planning outbound holiday sales. And a poor logistics strategy in the reverse flow can create refund delays and damage customer loyalty.

6. Customer-Facing Processes

Customer loyalty depends on smooth returns but for that to happen, returns policies must be written in clear language and communicated effectively. It should also not to be skewed to make the process challenging for customers. For instance by simply offering prepaid labels, drop-off points, or buy-online-return-in-store options, you can significantly reduce friction.

Fast refunds processed within five business days encourage buyers to shop again in the new year. And retailers that provide customers with convenience protect relationships at a moment when frustration is most likely.

7. Continuous Monitoring and Adjustments

Returns forecasting is not a one-time process. Actual return volumes often differ from estimates, so you must monitor daily return rates to adjust labor schedules, warehouse zones, and carrier allocations in real time. Post-season evaluation provides details for improvement in the next year and forecasting future returns improves with every cycle of measurement and adjustment.

Manage Returns Forecasting With ReverseLogix

ReverseLogix is built with meaningful metrics and game-changing insights in every module. With end-to-end returns management and best-in-breed tracking and analytics, ReverseLogix is the solution to ensure your post-holiday returns strategy actually leverages accurate returns forecasting and data. Request a demo to see what we can do for your returns.

Frequently Asked Questions

Returns forecasting helps retailers predict the surge of post-holiday returns and avoid operational challenges. By using historical data and forecasting models, companies can estimate return rates and prepare their operations team and fulfillment team to manage returned merchandise without bottlenecks.

Retailers should evaluate historical holiday sales, product categories, extended return policies, and consumer behavior such as bracketing or gift exchanges. External factors like shipping delays, economic conditions, and fraudulent returns also influence return rates. Accounting for these details leads to more accurate estimates.

Fast and clear returns provide customers with confidence and build customer loyalty. When companies forecast correctly, they allocate staff and resources to process refunds quickly. Smooth returns protect brand trust, encourage repeat purchases in the new year, and reduce stress for both buyers and gift recipients.

Operational readiness includes:

Allocating warehouse space for returned merchandise.

Hiring seasonal staff and training them to handle refunds.

Coordinating with carriers for extra capacity.

Using returns management systems to monitor daily volumes.

These steps improve operational efficiency and prevent bottlenecks.

Technology connects forecasting with execution. A strong returns management system gives customer service teams and managers real-time visibility of return items. It helps detect fraudulent returns, speed up restocking, and improve refund accuracy. Dashboards let companies track performance against forecasts and adjust resources when demand shifts.

Get a Demo

Discover how you can jump-start your returns management efforts with ReverseLogix.