B2B Reverse Logistics for High-Value Equipment

Summary

- High-value returns demand precision and control

- Automate RMA approvals to prevent costly errors

- Use serialized tracking for full return visibility

- Secure data handling protects sensitive information

- Document inspections to ensure accountability

- Integrate systems for real-time updates and efficiency

- Track performance to cut waste and recover value

A single mishandled return of a $50,000 device can cost more than ten successful shipments. Unfortunately, mishaps like that are not rare in the world of B2B reverse logistics. And despite that, many of these companies still treat B2B reverse logistics as a secondary concern. But when you’re handling high-value equipment, such a mindset puts more than the product at risk. It also puts your brand reputation, customer experience, and long-term cost savings in the same boat.

The question is, how can modern B2B reverse logistics workflows ensure high-value returns are traceable, secure, and cost-effective, so you don’t lose control when it matters most? Continue reading the article to find out:

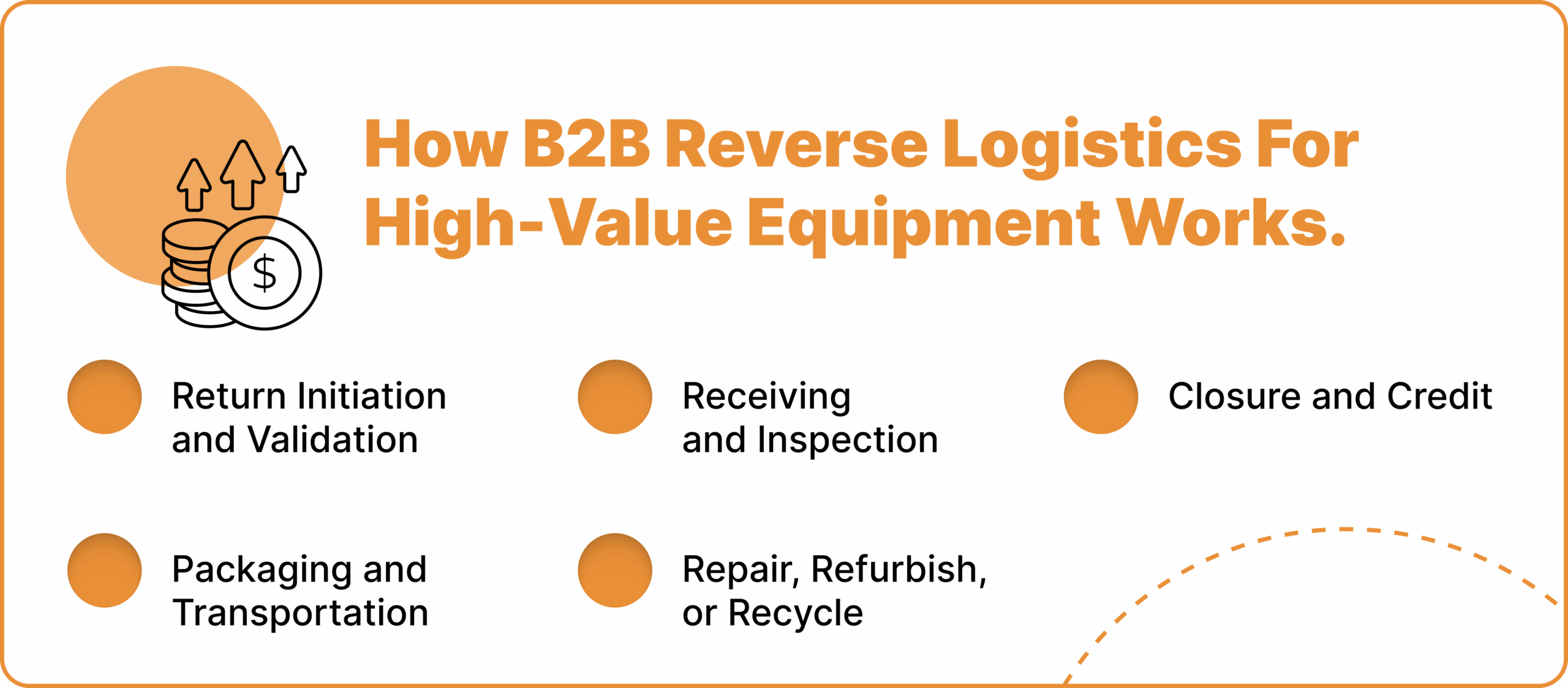

How B2B Reverse Logistics For High-Value Equipment Works

B2B reverse logistics for high-value equipment is not run with the same workflow as printer cartridges or T-shirts. Each stage must be locked down with process rules and checkpoints. For more context, here is how that works:

1. Return Initiation and Validation

When a customer or service team initiates a return request, typically through a customer portal or help desk, the returns management system checks product serial numbers, warranty terms, service contract details, and asset history before issuing a Return Material Authorization (RMA). This is important because it prevents unauthorized or duplicate returns.

For example, a telecom provider receives a return request for a rack-mounted server. The RMA system verifies that the server is under a support contract, linked to a specific site, and not flagged for data risk. When the RMA is approved, instructions on how to proceed with the entire returns and reverse supply chain process are sent to the field engineer or company representative.

2. Packaging and Transportation

The product is packed in reusable packaging designed to prevent damage and tampering. Following that, secure labels and sometimes RFID tags are attached to help track movement, and insurance is automatically applied for high-value shipments to protect against theft, damage, or fraud.

For certain pieces of equipment, such as medical devices or batteries, specialized carriers may be required to ensure a more seamless logistics process.

3. Receiving and Inspection

When the product arrives at the designated facility, warehouse management teams log the asset, photograph its condition, and match it with the RMA record. A thorough inspection then commences to check for physical damage, missing parts, or violations of the return terms and conditions.

For instance, if a diagnostic machine arrives from a hospital. The inspection team will check for contamination, confirm the model number, and scan the barcode into the inventory system. Any deviation from the expected condition flags the return for review.

4. Repair, Refurbish, or Recycle

Depending on the condition and the seller’s return policy, returned products may be restocked, repaired, refurbished, or recycled. For sensitive equipment, such as hard drives or mobile devices, secure data wiping is required and must be logged digitally. Once all of these steps are completed, the system updates the final disposition status and assigns the next steps.

5. Closure and Credit

Once the process is complete, the customer is notified. The return process updates accounting and inventory systems automatically, releasing refunds, credits, or replacement products as needed. This final step is critical, and the time it takes to progress from step one to this point plays a significant role in building confidence in your return operations and improving customer expectations for transparency.

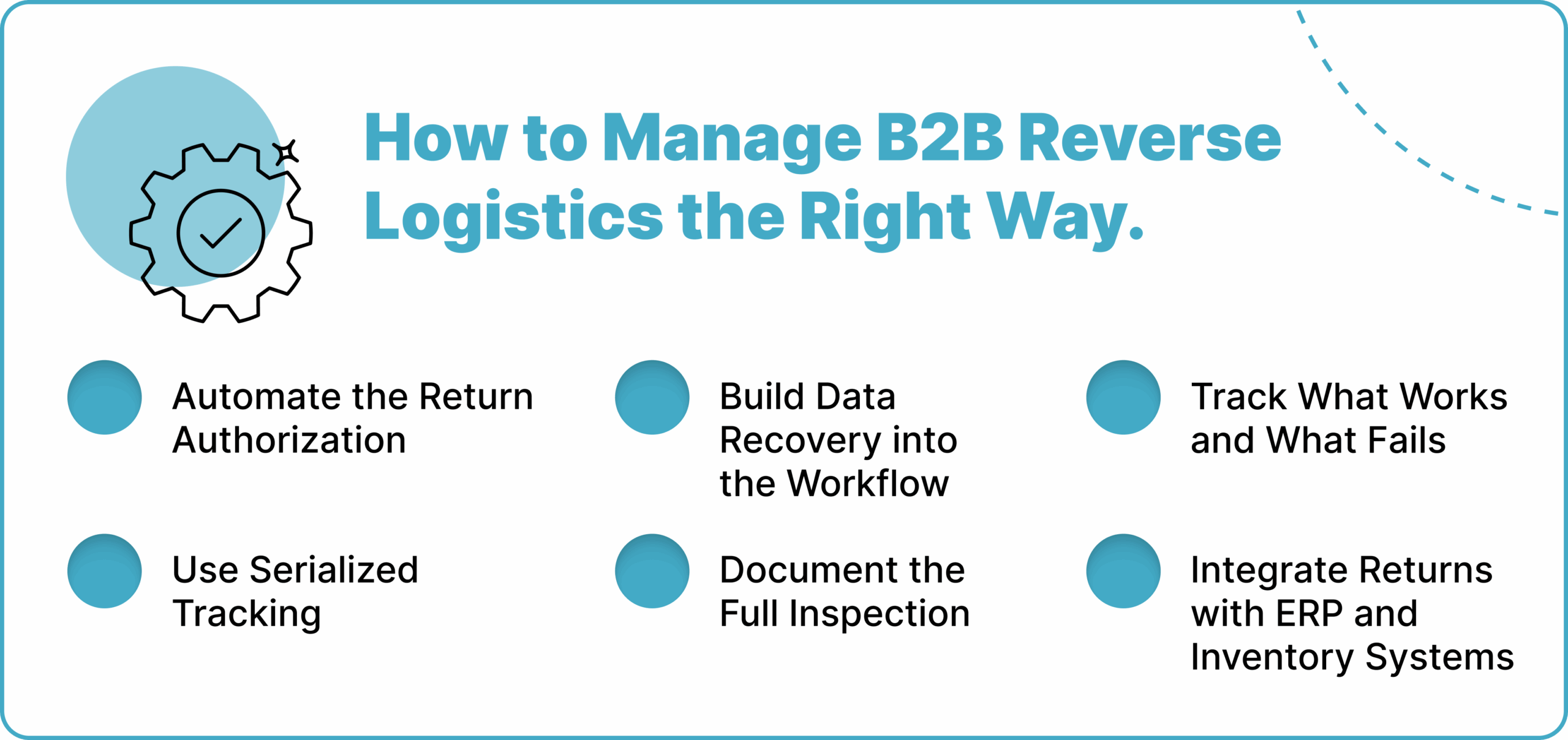

How to Manage B2B Reverse Logistics the Right Way

Not all systems can handle B2B reverse logistics for high-value items. However, for those who are successfully doing it, the common theme is structure. The more you can control, track, and document, the faster you recover value and reduce risks.

1. Automate the Return Authorization

Leveraging automated return initiation speeds up the turnaround and ensures that only the eligible product returns are processed. You can guide the automation process by setting rules for customers, contracts, device types, and return reasons. However, to ensure that, use structured online forms that prefill customer and asset data to reduce human error.

2. Use Serialized Tracking

Each returned item should be linked to a unique identifier or serial number. This way, you can track changes in condition, updates to location, and the status of repairs. RFID tags and scannable barcodes can automate much of this step, especially when handling large volumes in IT and telecom environments.

3. Build Data Recovery into the Workflow

In data loss situations, especially with hard drives, mobile devices, and telecom units, returned products may contain sensitive customer information. A secure data recovery process must confirm that information is wiped out before restocking or recycling. Attach a digital certificate of data wipe to each returned item and store them carefully for audit purposes.

4. Document the Full Inspection

Every product return should have photos, videos, and technician notes. This is the only way to defend against disputes and ensure the returned item qualifies for reuse or repair. Set up automated forms for inspection staff to reduce typing time and standardize the results.

5. Integrate Returns with ERP and Inventory Systems

Your returns management system shouldn’t sit alone. It must sync with and update inventory, service history, financial records, and even customer scorecards. Otherwise, teams work off old data, and returns get stuck in limbo. Ensure that you choose systems that offer native integrations or APIs for real-time synchronization.

6. Track What Works and What Fails

Many B2B teams fail to measure their reverse logistics operations, and those that do often do so ineffectively. However, tracking return volume, average cycle time, condition rates, and data recovery compliance can reveal significant improvements in the process. To get it right, monitor the top three return reasons by product line and address them at the source. That reduces waste and saves money in the long run.

Closing the Loop: From Risk to Results

B2B reverse logistics isn’t just about handling returns. It’s about recovering value, improving the customer experience, and minimizing waste. When done right, it protects margins, reduces transportation costs, and enhances inventory management accuracy. Returns don’t have to be a problem. When you partner with ReverseLogix, they become a way to reduce waste, improve asset control, and signal that your company cares about more than just the sale. Every return is an opportunity to improve and keep your customers satisfied.

Frequently Asked Questions

B2B reverse logistics deals with low-volume, high-cost returns like servers or medical devices, while B2C handles higher volumes of lower-cost consumer items.

Sectors like IT, telecom, and medical device companies often return mobile devices, hard drives, and diagnostic machines that require secure handling and inspection.

Using automated RMA approvals, serialized tracking, and integrated systems helps reduce waste, cut delays, and save money on returned items.

Returned products are validated, packed securely, tracked, inspected, and either repaired, reused, or recycled based on their condition and purpose.

Returned storage devices and mobile hardware are subject to verified data recovery processes, including secure wiping and audit-ready documentation.

Get a Demo

Discover how you can jump-start your returns management efforts with ReverseLogix.