How to Leverage Reverse Logistics Tech That Powers Asset Recovery at Scale

In 2026, returns management and asset recovery have come a long way. Unfortunately, many companies are still stuck in traditional, manual processes. The problem with that approach is that when you rely on manual steps or disconnected tools, the asset recovery process will more often than not break down. But with reverse logistics technology and asset recovery software, you gain more control over the recovery process.

Article Brief:

- Asset recovery improves when reverse logistics tech supports triage, inspection, resale decisions, and final disposition with automation and visibility.

- Automated systems reduce costs, save time, and improve operational efficiency by removing manual steps from the returns process.

- Real-time tracking and real-time updates reduce uncertainty for teams handling returned items and for shoppers waiting on refunds.

- Asset recovery software helps companies recover value from returned products by identifying resale potential, reuse options, or recycling paths early.

Consumers returned retail purchases worth a substantial $743 billion in 2023, about 14.5% of all sales. E-commerce buyers make returns at a rate 70% higher than brick-and-mortar customers.

In this article, we explore how reverse logistics technology gives retailers the systems needed to inspect, decide, recover, and report on returned assets at scale. Retailers face significant challenges in reverse logistics, such as high return volumes and processing difficulties, but the benefits of adopting technology include improved operational efficiency, cost savings, and enhanced customer satisfaction.

Why Asset Recovery Breaks Without the Right Technology

Asset recovery falls apart when decision-making is slow, and the value of the entire process is eroded through mistakes and costly disruptions. Without the right tech, returned products often sit in warehouses because there is no visibility into their condition, resale potential, or final disposition. And time erodes value, so every delay increases costs and reduces the likelihood of recovering higher value. Returns impact the bottom line because it costs retailers to store, process, and reclaim any possible value from returns.

Manual returns management creates blind spots. For instance, a manufacturer running a disconnected system may have spreadsheets tracking some assets, emails tracking others, and inventory management systems focused on outbound sales rather than returned items. Without one platform, that manufacturer will lose control. The varied nature of returns requires different approaches and investment of time and resources from the retailer. But with the right asset recovery software, the same manufacturer can effectively close that gap by creating visibility across the reverse supply chain.

As Gartner notes, companies that automate reverse logistics processes improve return processing speed and reduce errors associated with human handling. Technology does not replace judgment. It removes guesswork. The ability to manage returns efficiently is crucial for operational efficiency, and having a clear plan and the right resources can make a significant difference in optimizing reverse logistics tech.

What Asset Recovery Looks Like Without The Right Reverse Logistics Technology

Without the right tech solution in the asset recovery process, you may have a process that looks somewhat like this:

Retailers and online shoppers face significant challenges in processing returns, as the growing volume of e-commerce purchases leads to increased return rates and higher customer expectations. Returns create additional freight, inspection, and warehousing costs.

Manual workflows, disconnected systems, and lack of visibility can lead to lost inventory, delayed refunds, and dissatisfied customers. The absence of automation also makes it difficult to optimize shipping and return shipping, both of which are critical for an efficient reverse logistics process.

Additionally, handling high volumes of returns requires robust fraud prevention measures to identify suspicious activity and protect revenue.

1. The Value of the Returned Products is Drained

For instance, imagine teams inspecting returned items one by one without any standard rule to guide their decisions. Automated systems can streamline the inspection process, saving time and reducing costs by automating repetitive tasks and minimizing manual errors. High volumes will overwhelm them. Automated systems can cut return processing times by up to 50%. And worse, some of these items will have to wait longer than necessary while the cost of the inspection climbs.

2. Lack of Visibility Compounds the Problem

Once an item leaves the store or the customer, tracking becomes less reliable. Real time updates and tracking and visibility tools — such as barcode scanning, RFID, and QR codes — can monitor returned items, their condition, and location, improving transparency and coordination throughout the returns process. Usually, in this sort of scenario, the warehouse teams do not know what is coming, nor do the finance teams know what value to assign to the returned items. As a result, the customer experience suffers because refunds slow down and updates stop. It is a ripple effect that ultimately costs you more and damages your brand reputation.

3. Scale Magnifies Every Weakness

Online retailers processing thousands of returned products face higher return rates, fraud risk, and storage pressure. Meeting customer expectations for fast, hassle-free returns can provide a significant competitive advantage and is essential for building customer loyalty. Without reverse logistics automation, chaos grows faster than headcount can keep up. Over 80% of online shoppers will avoid retailers who don’t provide free or simple return policies, underscoring that poorly handled returns affect customer loyalty and customer retention.

What Asset Recovery Software Actually Does

Asset recovery software moves recovery from a reactive to a controlled process. It goes beyond basic returns tools by managing assets through inspection, decision logic, and reporting. Some of the core capabilities include:

- Reporting tied to recovery outcomes

- Centralized intake for returned items

- Rules-based routing by condition and value

- Decision support for resale, repair, or disposal

- Ability to recover value from returned assets, maximizing product value and recouping costs

The benefits of using asset recovery software include increased operational efficiency, cost savings, improved customer satisfaction, and enhanced environmental sustainability. Many businesses use Return Merchandise Authorization (RMA) tools to approve and track returns before they reach the warehouse, streamlining the returns management process. Top reverse logistics platforms are designed to integrate with existing business systems, including e-commerce platforms and internal systems, to handle the rising volume and complexity of online retail returns. Robotics and AI are leveraged in reverse logistics tech to efficiently process high volumes of returns, while AI-based analytics help automate the returns process and support intelligent, timely decision-making.

Reverse logistics tech connects return data, inventory, and warehouse operations. This way, your returns team can see where assets are in real-time, what actions remain, and how much value can still be recovered.

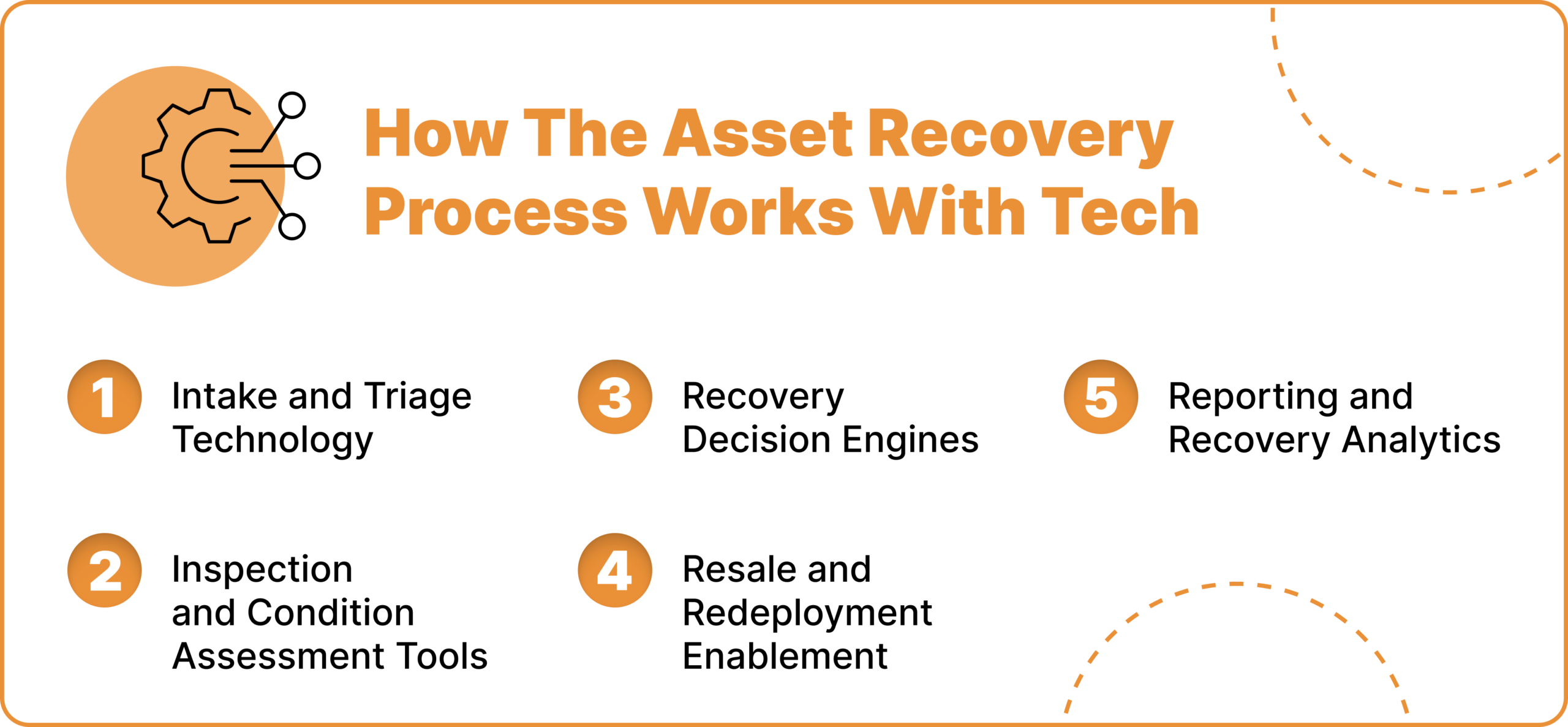

How The Asset Recovery Process Works With Tech

Asset recovery software plays a key role in every stage of the process if used correctly. Automated systems enable real-time analysis of return data, which helps businesses improve product descriptions and quality control. AI analyzes return data to identify patterns and trends, allowing companies to enhance product quality and reduce future returns. Additionally, AI-driven tools can identify fraud early in the returns process, supporting effective fraud prevention. Here is what that entails:

Stage One: Intake and Triage Technology

Asset recovery starts at intake. Digital intake tools capture key information such as serial numbers, asset type, return reason, and the location where a return begins. That data links each asset to history and ownership.

Automated triage rules route assets before human delay sets in. For instance, a laptop returned for warranty work automatically moves to inspection. And a damaged item flagged for low resale potential is routed to recycling. Basically, the algorithm reduces hesitation and speeds up decision-making.

Stage Two: Inspection and Condition Assessment Tools

IT assets require data wipes, medical devices require safety documentation, and industrial tools require calibration records. Compliance controls sit within inspection workflows. So, keeping digital records of every check is crucial because they serve as proof that your company followed the rules.

Inspection tools standardize how teams assess the condition of the recovered assets. This way, every warehouse follows the same steps. And guided checklists replace tribal knowledge. Asset recovery software enforces this alignment across locations, ensuring that one team’s “repairable” matches another’s, as consistency is critical.

Stage Three: Recovery Decision Engines

Decision engines remove emotion from the asset recovery process. They are part of the system that decides what should happen to a returned asset next, based on rules and data rather than human guesswork.

The recovery engine can compare repair costs, resale potential, and remaining product life cycle in real time. With that, you can answer clear questions, such as: does the repair cost exceed the resale value, is demand high enough to resell, and should the asset be returned to inventory?

Predictive analytics strengthens these decisions by learning from past returns. If data shows that a certain type of asset performs better in resale than in redeployment, the system applies that knowledge automatically as volume increases.

Stage Four: Resale and Redeployment Enablement

Once an asset is inspected and a decision is made, it must follow a defined path rather than sit in limbo. And with asset recovery software, you can make sure each path is clear, supported, and enforced. For example, internal redeployment routes usable assets back into operations. This way, the IT teams reuse hardware, field teams reuse tools, and manufacturing avoids new spend.

For the products that will go into the secondary market resale, accurate grading and clear records are required. To protect brand trust, tech is used to ensure that product quality details match reality. Reselling the refurbished products depends on visibility. Without tech, the assets drift until they lose value, but with tech, recovery stays intentional.

Stage Five: Reporting and Recovery Analytics

Reporting holds the system together. Without it, teams will repeat mistakes. But with solutions like asset recovery analytics, you can track:

- Recovery value per asset

- Time to final disposition

- Repair versus resale ratios

- Cost versus revenue outcomes

By leveraging automation in reverse logistics tech, companies gain the ability to improve operational efficiency and recover more value from returned products. The benefits include streamlined processes, faster processing, better space utilization, and minimized errors, all of which cut labor, storage, and operational costs in reverse logistics. Effective reverse logistics management can save up to 25% of total logistics costs by recouping losses through product refurbishment or resale.

These metrics reveal where the money is lost or recovered. And they also show which products fail early and which return paths perform best.

What to Look for in Asset Recovery Software

Not all tools support recovery at scale. Retailers and manufacturers should look for:

- Condition-based routing

- Configurable workflows by asset type

- Strong reporting tied to recovery outcomes

- Support for tracking across warehouse locations

- Integration with returns management and inventory systems

- The ability to manage resources effectively, ensuring optimal use of time, labor, and financial investment throughout the reverse logistics process

- Fraud prevention features and real time updates to enhance transparency, protect revenue, and keep all stakeholders informed at every stage

The right investment supports business growth, protects money, and keeps customers coming back.

How ReverseLogix Enables Asset Recovery at Scal

Asset recovery scales when one system replaces scattered tools. ReverseLogix gives warehouses, repair centers, and external partners a single platform to work from, so everyone sees the same asset data simultaneously. That shared view removes delays caused by handoffs and follow-ups.

Automated systems within ReverseLogix streamline returns handling, saving time and reducing errors, which not only boosts efficiency but also helps in keeping customers coming back by providing a smoother, more reliable return experience.

Automation inside ReverseLogix replaces manual coordination. Assets move automatically from intake to inspection, decision, and final disposition based on rules. Fewer touchpoints mean fewer errors. And faster movement shortens processing time, improving the return experience with quicker refunds and timely updates.

As volumes grow, the system holds steady. ReverseLogix is built to handle high return rates without breaking workflows or losing visibility. Growth becomes manageable because the platform enforces consistency. Get a demo today to see how it works.

Frequently Asked Questions

Reverse logistics technology provides the systems needed to track returned products, assess condition, and guide recovery decisions. By automating these processes, it significantly improves operational efficiency and enhances the ability to recover value from surplus assets. Without it, asset recovery relies on manual judgment, which slows processing and increases costs.

Asset recovery software uses return data, inspection results, and predictive analytics to guide decisions on repair, resale, or disposal. This helps companies recover higher value instead of guessing or delaying action.

Technology removes friction by automating routing, enabling real-time tracking, and standardizing inspection steps. This creates easy returns for shoppers and faster processing for warehouse and operations teams. The benefits of automation and real time updates include greater operational efficiency, cost savings, and improved transparency throughout the returns process, which directly contribute to higher customer loyalty by reducing friction and keeping customers informed at every stage.

Yes. Faster processing, accurate tracking, and predictable refunds improve the return experience. When customers trust the system, customer satisfaction increases and repeat purchases become more likely.

Retailers should focus on one platform that supports high volumes, integrates with inventory systems, provides visibility across locations, and offers reporting that ties recovery actions to revenue and costs. It is also crucial to choose a solution that gives retailers the resources and ability to manage returns efficiently, while incorporating robust fraud prevention features to protect against return fraud.

Get a Demo

Discover how you can jump-start your returns management efforts with ReverseLogix.