Maximizing the Value of Used Equipment: Inside an Asset Recovery Workflow

Most manufacturers treat returned items as clutter—something to discard, replace, or write off. But that kind of attitude will, more often than not, mean they leave more money on the table than they would like. In today’s business environment, asset recovery is no longer just a side project that was optional. It is now, more than ever, a supply chain opportunity.

Article Brief:

- Asset recovery works best when companies follow a clear process that starts with return authorization and ends with redeployment, resale, or recycling.

- It protects capital by determining whether equipment should be sent to repair departments, resold, used for parts recovery, or disposed of.

- Industries such as IT hardware, medical devices, and industrial tools benefit most when recovery decisions follow the product life cycle.

- Tracking asset recovery across countries supports better decision-making in foreign jurisdictions and reduces risk associated with shipping and compliance.

When returns are handled with structure, retailers and manufacturers can recover value, control losses, and reduce waste. A strong asset recovery process turns returned items into recovered value by following a clear workflow that starts at intake and ends in resale, redeployment, or responsible recycling.

What Asset Recovery Really Means

Asset recovery is the structured process of recovering the value of a product after it has been returned, retired, or unused. More than just recycling or proper disposal, asset recovery is about identifying products or assets that can still serve people or customers and how to do so effectively.

Businesses use asset recovery to reclaim value from IT hardware or assets, medical equipment, and industrial tools after lease expiry, delivery failure, or warranty work. This includes returned products, overstocked items, or defective equipment. The return process opens a window where smart recovery planning can preserve capital.

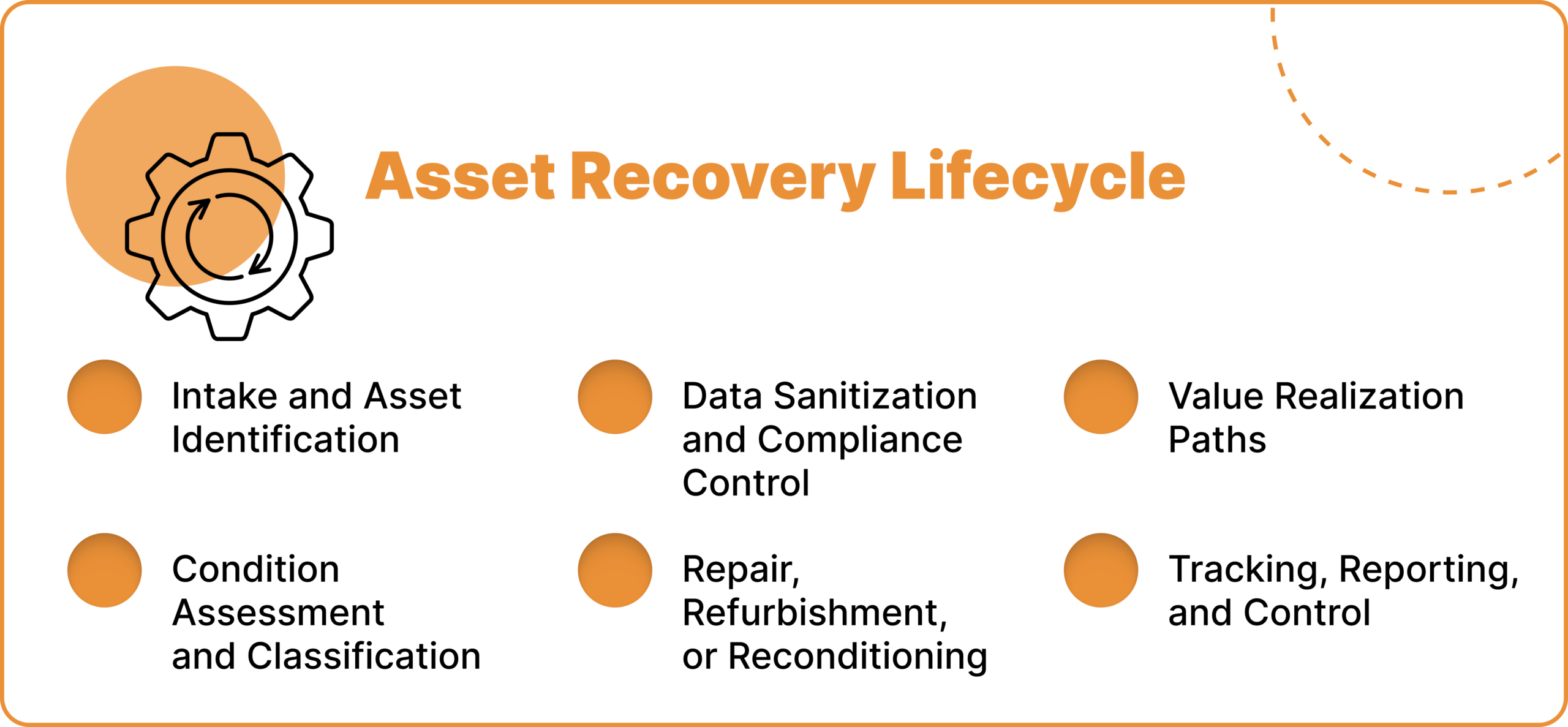

Step One: Intake and Asset Identification

A recovery workflow kicks off when an item re-enters the supply chain. But this moment is when most companies make their first mistake, which is failing to capture the right data. Every item should be logged with its serial number, return category, condition, usage history, and reason for return. Whether the issue was poor sales, a shipping error, a delivery refusal, or a product failure, the return’s origin matters. Particularly because it helps assign accountability, track financial data, and determine the most profitable next step.

In IT, this might involve leased laptops returned after a refresh cycle. In medical device manufacturing, it could be equipment pulled from hospitals after a device recall. In industrial supply, think of field tools returned from job sites after project completion.

Step Two: Condition Assessment and Classification

Once assets are identified, they need to be tested. This means checking for functionality, cosmetic damage, software lockouts, and compatibility. One returned product may work perfectly, but another might have a failed board or a missing part. After each assessment, the assets are placed into one of several categories:

- Repairable with minimal cost

- Recoverable only as components

- Beyond repair and fit only for disposal

- Fully functional and ready for redeployment

Medical devices must pass safety and sterilization standards. Industrial tools may need recalibration or replacement of parts. IT assets need software access verification. The reverse logistics process only works when this sorting step is clear and backed by a structured return authorization system that links each asset to its service history.

Step Three: Data Sanitization and Compliance Control

No asset recovery plan is complete without data handling. For IT equipment, residual data means legal and reputational risk. A Blancco study found that 42% of used drives sold online still contained readable personal or corporate data. That figure alone shows why sanitization must happen before redeployment or resale.

Sanitization methods include:

- Drive overwriting.

- Secure erasure certificates.

- Physical destruction for non-wipeable drives.

Medical device manufacturers must follow state and national level regulations that require device tracking, decontamination, and documentation. In highly regulated environments, Chapter V of the UN Convention against Corruption outlines how confiscation and disposal must respect legal ownership and country-level agreements.

Step Four: Repair, Refurbishment, or Reconditioning

After classification, the business decides whether to repair, refurbish, or part out the asset. This choice should weigh the repair cost, the asset’s age, the remaining product life cycle, and internal demand vs. resale value. Here are some examples:

- A laptop is cleaned, reimaged, and reassigned to a new hire.

- A returned infusion pump is refurbished and sold into a secondary market where the model is still accepted.

- A hydraulic tool is repaired by the manufacturer’s own repair department and used as a backup in field service.

Manufacturers who have a solid reverse logistics plan bake repair into their workflows and track each decision for audit and improvement.

Step Five: Value Realization Paths

Once an asset has been restored or triaged, it enters a recovery path. And each of these paths has its own benefits and logistics considerations. For instance:

Internal Redeployment

This saves the company money by using the asset internally instead of buying new equipment. IT and field operations benefit most from this path.

Secondary Market Resale

Assets in good shape but no longer needed internally can be sold through certified channels. A clear reverse supply chain strategy ensures the item is listed accurately with proper disclosures.

Parts Harvesting

When an asset isn’t functional but its components are, it enters parts-harvesting. These parts support maintenance, warranty work, or product support—adding value back to the service arm.

Responsible Recycling

When all else fails, the asset is recycled with certified partners. Proper documentation helps the business prove compliance, track proceeds, and avoid environmental risk.

The returns management system should record which assets go down each path and why to create insight for forecasting and procurement.

Step Six: Tracking, Reporting, and Control

Without visibility, asset recovery breaks down. Tracking every item’s location, status, and assigned recovery path keeps the workflow clean and protects the company’s ability to meet customer expectations.

Strong tracking systems support financial reconciliation, warranty auditing, compliance checks, and cross-team coordination. Good reporting also shows the value recovered per return category, turnaround time, and rate of internal redeployment. These numbers influence decisions on warranty terms, return policies, and product packaging.

Over time, this data helps identify trends such as which product lines have higher return rates, which foreign jurisdictions are slow to clear international returns, or which support teams are logging incomplete return records. That level of control strengthens the entire reverse logistics chain.

How ReverseLogix Supports Asset Recovery at Scale

ReverseLogix powers a structured asset recovery process from intake to resale. It offers:

- A unified return process with clear workflows

- Visibility across all return categories and asset types

- Real-time tracking from point-of-return to final disposition

- Compliance support for sectors that face regulatory pressure

- Data that helps manufacturers reduce waste and reclaim revenue

Retailers and manufacturers leverage ReverseLogix to coordinate across the repair department, customer support, logistics teams, and warehouse staff. Whether you’re dealing with returned items, delivery-refusal cases, or aging equipment from international contracts, the platform helps you sort, track, and recover value without delay.

As reverse logistics refers to everything that happens after the sale is complete and the customer wants to make a return, ReverseLogix becomes the central command center for that entire supply chain process.

Frequently Asked Questions

Asset recovery is the process companies use to reclaim value from returned or unused equipment. In reverse logistics, asset recovery refers to identifying assets, assessing condition, and determining whether they should be repaired, reused, sold, or recycled rather than written off.

[Unverified] A structured asset recovery process prevents returned items from sitting idle. When companies identify assets early, they can recover money through resale, parts harvesting, or redeployment instead of losing value through disposal.

Recycling is only one outcome of asset recovery. Asset recovery focuses first on reuse, repair, or resale. Recycling becomes the final step when equipment no longer holds usable value.

Manufacturers face delivery failure, defective products, warranty work, and delivery refusal. Asset recovery helps manufacturers manage returned items, protect revenue, and deal with different types of equipment without increasing waste.

Asset recovery strengthens the supply chain by returning usable assets back into circulation. This reduces the need for new production and supports a stable reverse supply chain.