The most sustainable product returns are those that never happen.

In a world ever-more conscious of its buying habits, improving how you manage product returns will support corporate sustainability efforts, lower costs and strengthen customer loyalty and brand longevity. Remember: A product return is a negative environmental impact – without a net sale to justify it!

What’s Preventing More Sustainable Returns?

One of the biggest barriers to minimizing returns is the lack of understanding as to why returns are made in the first place. Better visibility into returns data, reasons, trends, costs, and sustainability impacts will help you develop a plan for preventing returns.

- Are there sourcing issues and defects?

- Do certain items or brands have high returns rates?

- Could you improve tracking visibility and processing transparency across a vendor ecosystem?

Most retailers do not understand the full unit economics of returns…Without this visibility, decisions are being made on an ad hoc basis, and the root causes cannot be addressed.

– McKinsey

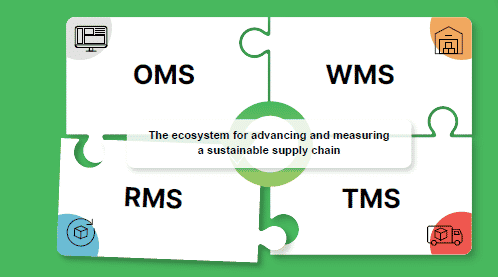

The reason for the lack of good data has been the lack of supply chain software capabilities specific to returns management. Companies have had to piece together ERPs, WMSs, and other systems in order to process returns and cobble together metrics.

It’s all in the Data

B2C and B2B companies now have a solution for understanding how return logistics effect sustainability efforts: A returns management system (RMS).

An RMS is the master returns system for more efficiently managing product returns, minimizing unnecessary returns, and for insights that help you make informed decisions around sustainability.

It manages returns initiation, processing, repairs, and disposition, and everything in between. The flexibility of the technology allows you to configure rules, policies and workflows that align your sustainability goals with on-the-ground action, such as priorities around remarketing or recycling.

The power of an RMS is the quality of its data. It centralizes and analyzes information from core supply chain systems, connecting directly to all business intelligence applications in order to deliver powerful BI and data analytics. With it, you can finally overcome one of the biggest barriers to sustainable product returns and achieve end-to-end returns data to…

- Prevent unnecessary returns

- Facilitate re-commerce and restock opportunities

- Minimize emissions and packaging waste

- Prioritize repairs and recycling

It’s time to get serious about sustainability in returns management! For more details about how an RMS drives sustainable returns, efficiency and cost savings, download our white paper.