The Role of Reverse Logistics in Sustainable Practices: Optimizing for Eco-Efficiency & Circularity

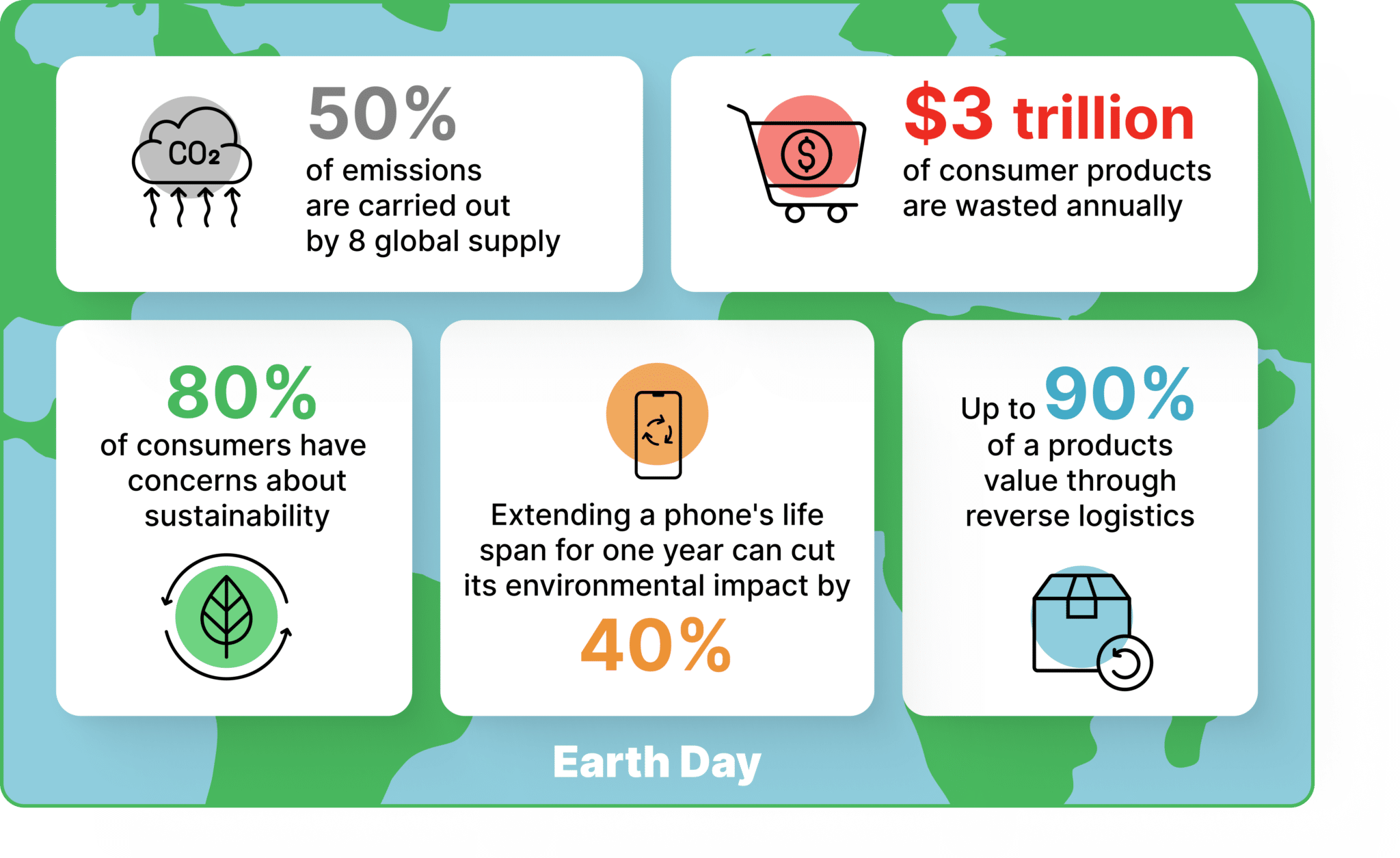

Reverse logistics sustainability is gaining attention as the market moves toward more circular models, with it being reported that reverse logistics is on track to pass USD $1 trillion by 2033. Research also notes how e-commerce returns generate about 24 million tons of CO₂ and contribute to more than 62 million tons of global e-waste each year. Below, we’ll look at how a strategic approach to reverse logistics can cut environmental impact, recover value, and create actual gains for organizations working toward a sustainable future.

Key Takeaways:

- Reverse logistics sustainability supports circular economy goals and creates steady value recovery across product categories.

- Growing return volumes highlight the need for stronger systems that reduce waste and improve material return.

- AI, automation, and modern tracking tools make return operations faster and more accurate.

- Circular strategies lower material demand and decrease emissions while providing financial gains.

- Sustainable reverse logistics strengthens long-term stability by reducing dependence on new materials and external suppliers.

From Linear Waste to Circular Value

The shift from a one-directional flow of products to a circular model changes how companies think about materials, returns, and long-term value. Below, we’ll look at the environmental pressure created by growing returns volumes, the limits of traditional systems, and how reverse logistics opens the door to actual circular value.

The Returns Tsunami: Environmental Costs and Operational Challenges

E-commerce returns create severe pressure on the environment. In fact, return activity produces about 24 million metric tons of CO₂ each year and contributes to more than 62 million tonnes of e-waste. It was also found that more than 9.5 billion pounds of returned products were landfilled in 2022. These volumes strain daily enterprises because large return flows often lead to extra shipping and high processing expenses. Generous return policies also increase volume, which adds more waste and pushes costs higher for every team involved.

Why Traditional Supply Chains Are No Longer Sustainable

Traditional supply chain sustainability is hard to maintain because the “take-make-dispose” approach depends on steady access to new materials. As e-commerce grows and new regulations arrive, this structure cannot keep up with demand for responsible production. Many systems also stop tracking value once a product reaches the buyer, leaving no path for reuse or recovery. Without Product Lifecycle Management guiding the whole journey, companies lose materials that could otherwise stay in circulation.

| What is the difference between recyclability and circularity? Recyclability means a product can be processed for reuse. Circularity includes recycling but focuses on keeping materials in use longer through reuse, repair, or resale. |

Reverse Logistics as the Strategic Imperative for a Green Future

Sustainable reverse logistics creates a planned path for collecting, moving, and processing products after use. It supports reuse, repair, recycling, or responsible disposal, making it the link that allows a circular economy to function. This network reduces waste and emissions while also opening new ways to regain revenue through refurbished or resold items. This is how reverse logistics contributes to sustainability: it lowers the environmental impact by keeping valuable materials working longer instead of moving straight to disposal.

Optimizing Reverse Logistics for Sustainability

Building a more sustainable enterprise begins with clear plans for how products move back through the supply chain. Below, we’ll look at the market forces shaping sustainability in supply chain planning, the economic case for green returns, and the strategies companies use to recover more value while lowering environmental impact.

The Economic Case for Green Reverse Logistics

Sustainability in reverse logistics continues to grow as a core business priority. In fact, the global reverse logistics market was valued at about USD $835 billion in 2025 and is expected to reach USD $1.03 trillion to $1.43 trillion by 2033-2035, with CAGRs (Compound Annual Growth Rate) between 4.8% and 7.2%. Regulatory pressure, especially from the EU, and rising consumer interest in greener brands drive this momentum. Companies also turn to reverse logistics because it strengthens long-term performance and creates steady gains through better material recovery and resale channels.

Strategic Approaches to Green Reverse Logistics

Automation and AI play a direct role in improving material recovery, and it’s been reported that robots and AI systems can raise recovery rates by 40-50% and reduce labor costs by 20-30%. Another approach is to connect forward and reverse flows, which can raise transport efficiency and cut emissions by up to 39%. Quick, rules-based disposition, whether the item should be resold, refurbished, or recycled, keeps products moving and reduces holding time, allowing companies to regain value sooner and minimize waste.

Reverse Logistics Best Practices for Sustainability

Strong reverse logistics programs start with clear environmental metrics such as waste diverted, recovered components, and return reasons. Data platforms make it easier to track performance and uncover patterns that can guide prevention strategies. Investment in AI and automation improves sorting, grading, refurbishment, and recycling, which increases recovery rates at scale. Many companies also build local refurbishment hubs or processing centers to shorten transport distance and follow shifting environmental regulations more easily.

Circular Economy Strategies: Closing the Resource Loop

Circular economy sustainability depends on systems that keep materials in use for as long as possible. Reverse logistics plays a central role in this shift by creating steady pathways for returns, repair, recycling, and resale. Below, we’ll explain how these loops work, how value recovery supports product lifecycle planning, and how global policies push companies toward circular models.

Defining the Link: How Reverse Logistics Enables the Circular Economy

Reverse logistics is the foundation of circular economy sustainability because it enables every loop that keeps materials in circulation. It creates the structure needed to return products, repair them, recycle components, or move them back into resale channels. This approach transforms a single-direction supply chain into a flexible, multi-directional network focused on preservation rather than disposal. It also strengthens product lifecycle management by extending how long materials remain useful.

Value Recovery: Extending the Product Lifecycle

Remanufacturing and refurbishment offer practical ways to extend the product lifecycle. Both processes restore products or components to a like-new state, which lowers demand for new material production. Companies also rely on a clear recovery hierarchy: reuse and resale offer the strongest returns, followed by repair and refurbishment, then remanufacturing, and finally recycling. End-of-life returns, especially e-waste, hold valuable metals and components that secondary manufacturers can use, making remanufacturing a key part of long-term resource planning.

Driving Forces and Frameworks for Circular Supply Chains

Circular economy principles are now gaining traction as companies use reverse logistics to reduce waste, increase recycling, and extend product lifecycles. Regulations such as the EU’s Waste Electrical and Electronic Equipment (WEEE) Directive and Circular Economy Action plan add pressure for companies to adopt stronger circular systems. Successful circular logistics frameworks focus on integrated return flows, automated condition assessment, and close coordination across partners. These systems rely on clear internal guidelines, advanced tracking technology, and collaboration across the supply chain to keep materials moving.

Key Benefits of a Circular Supply Chain for Businesses

Circular logistics frameworks show clear gains for organizations. Logistics Management reports that companies can lower raw material costs by 20-40% when they reuse components. These frameworks can also reduce total emissions by up to 39% when return flows and material recovery are integrated into regular enterprises. Another benefit is greater resilience, as companies that rely less on new materials and external suppliers remain steadier through price swings and global disruptions.

Leveraging Technology for Sustainable and Efficient Returns

Technology is now at the center of modern reverse logistics. Tools like AI, IoT (Internet of Things), and blockchain make it easier to track items, assess product conditions, and create faster recovery paths. Below, we’ll look at how these technologies improve daily enterprises, raise recovery rates, and support long-term sustainability goals.

How Technology Improves Reverse Logistics Efficiency

AI, IoT, and blockchain give teams clearer visibility into every return. IoT devices track items through each step, which reduces loss and keeps the return status accurate. AI sorts products, identifies condition issues, and guides quick routing decisions. Blockchain creates a secure record of product movement and material use, which supports transparency and ensures companies meet environmental requirements. Together, these tools make return operations more predictable and easier to manage.

The Critical Role of AI in Reverse Logistics for Sustainability

AI plays a leading role in sustainability returns because it improves accuracy and makes evaluation faster. Machine Learning models review product condition and automate decisions for resale, repair, or recycling. AI analytics also uncover the root causes of returns, such as sizing concerns or unclear product descriptions, which allows teams to reduce volume return over time. Automation supported by AI can also move more progressive workflows faster, including battery and e-waste processing, sometimes at rates up to three times higher than manual work.

Choosing the Best Reverse Logistics Software for Sustainable Returns Management

Strong reverse logistics software should support AI and automation so teams can make fast, rules-based decisions on each item. ESG (Environmental, Social, and Governance) and data reporting features let companies measure environmental performance and share results across the organization. Integration is also vital; the platform should connect easily with forward logistics systems and work with circular economy programs. A scalable platform gives teams the ability to manage B2B (Business-to-Business), B2C (Business-to-Consumer), and hybrid return streams as volume grows.

The Financial Impact: Measuring the ROI of Sustainable Returns Initiatives

Sustainable returns programs produce measurable financial gains when companies bring circular thinking into their enterprises. Below, we’ll outline how organizations cut costs, grow recovery revenue, and make reverse logistics a dependable source of long-term ROI (Return on Investment).

Direct Cost Reduction Methods in Reverse Logistics

Reverse logistics lowers direct operating costs in several ways. Automation used in sorting and refurbishment can cut labor expenses by 20-30%, which creates immediate savings. Circular models reduce raw material demand, and companies that reuse or remanufacture components often lower raw material costs by 20-40%. Integrated transport planning also uses fewer miles and less fuel, which lowers overall logistics spending. These gains show how reverse logistics strengthens both environmental and financial performance at the same time.

The Comprehensive ROI of Sustainable Reverse Logistics Initiatives

Sustainable reverse logistics creates returns across several categories. Companies measure ROI through reduced labor and material costs, higher revenue from refurbished or resold items, and lower disposal fees. Strong programs also reduce regulatory risk because they follow environmental rules more regularly. Many organizations also see higher customer loyalty when they offer reliable repair, recycling, or take-back options. These gains work together to raise long-term profitability.

Strategic Investment Areas for a Strong Cost-Benefit Analysis of Green Returns

Sustainability in reverse logistics often begins with targeted investment. Modern RMS (Returns Management System) platforms, AI-driven sorting tools, and blockchain tracking improve accuracy and make daily operations easier. Dedicated refurbishment hubs and collection points shorten transport and support faster processing. Many companies also invest in training so teams can work with new digital tools and review environmental results more clearly. These areas form the base for a strong cost-benefit analysis and steady improvement over time.

Transforming Risk Into Resilience

Sustainable reverse logistics gives companies a clearer path forward by reducing waste, improving recovery, and creating steady financial gains. When organizations rethink how products move after the point of sale, they turn risk into long-term resilience and build systems that can adjust to market shifts and resource constraints.

Next Steps:

- Review your current returns workflow and identify where material loss or long wait times occur.

- Set clear environmental and financial metrics to track recovery rates, return reasons, and route decisions.

- Evaluate reverse logistics software that supports automation, AI, and ESG reporting.

- Consider local refurbishment or processing hubs to reduce transport distance and improve turnaround time.

- Build cross-team planning sessions to match forward and reverse flows under one scalable approach.

Ready to strengthen your reverse logistics program and build a more sustainable returns strategy? Connect with ReverseLogix to explore a platform designed for actual recovery, circularity, and long-term resilience.

Frequently Asked Questions

What is sustainability in reverse logistics?

Sustainability in reverse logistics involves managing product returns and end-of-life disposal to minimize environmental impact. It prioritizes recycling, refurbishing, and remanufacturing to extend product lifecycles. By reducing waste and carbon emissions during these processes, companies maximize value recovery while supporting a circular economy.

What are the 4 A’s of sustainable logistics?

The 4 A’s of sustainable logistics are Awareness (recognizing environmental impact), Avoidance (eliminating unnecessary transport and packaging), Acting (shifting to greener transport modes), and Anticipation (preparing for future regulations). This framework helps businesses systematically reduce their carbon footprint while maintaining operational efficiency.

How to make logistics sustainable?

To make logistics sustainable, companies should optimize delivery routes to save fuel and transition to electric vehicle fleets. Additionally, using biodegradable packaging, installing renewable energy systems in warehouses, and practicing shipment consolidation to reduce empty miles are critical steps for lowering the supply chain’s environmental impact.

What is the framework of reverse logistics?

The framework of reverse logistics typically involves five key stages: gatekeeping (return authorization), collection, inspection/sortation, disposition (repair, resell, recycle), and redistribution. This structured approach ensures returned products are processed efficiently to recover maximum value, minimize landfill waste, and ensure proper final disposal.

What are the five pillars of logistics?

The five pillars of logistics are Transportation, Inventory, Warehousing, Packaging, and Information. Together, these components ensure the smooth flow of goods: transportation moves products, inventory manages supply levels, warehousing stores goods safely, packaging protects items, and information coordinates the entire network for efficiency.

Works Cited

Reverse Logistics Market Outlook

From Cart to Landfill: Reducing Retail Waste with Sustainable Returns

Reverse Logistics in 2025: Turning returns into a competitive advantage

Get a Demo

Discover how you can jump-start your returns management efforts with ReverseLogix.