Why Reverse Logistics Needs a Seat at the Product Lifecycle Management (PLM) Table

Reverse logistics and returns management are often an afterthought when planning and setting up the product life cycle management. Most manufacturers see it as something to handle after the sales is through and customers are trying to make their returns. The problem with that approach is that it:

- Creates waste

- Breaks supply chain links

- Increases the cost of the entire reverse supply chain management.

The smart move is to treat reverse logistics as part of product lifecycle management from the beginning. With such a shift, it will change how companies design, build, recover, and reuse their products. Integrating both operations from the start will connect supply chain activities with returns, repairs, and recycling. It will also reduces waste and pollution, protect profit margins, and improves customer satisfaction.

Now, the question is how to achieve this and ensure such integration works seamlessly. This article will explain why and show you how to bring reverse logistics into your product development process without disrupting the entire supply chain operation. Continue reading to find out more:

Reverse Logistics Is Not Just Cleanup

The problem with the way many manufacturers view reverse logistics is that they see it as a necessary evil rather than an opportunity. An opportunity that ensures you can mitigate the cost of customer satisfaction in an era where their demands are increasingly more nuanced.

Keeping reverse logistics outside your product’s lifecycle creates additional cost. But most manufacturers realize this too late. This means they get stuck reacting to broken returns, and struggling with delivery failures, excessive inventory, or expired stock. This is because the problem isn’t downstream, it’s upstream.

When reverse logistics is excluded from early design, product recovery becomes harder. Without complete product data management (which includes returns data), your repair team is left guessing, which slows down the process. Without PLM integration, your warehouse handles returns blindly. That leads to poor recovery, bad refurbishing, and higher supply chain costs.

Instead of wasting valuable time fixing this later, it can begin during the product design phase, which makes your entire operation much more seamless.

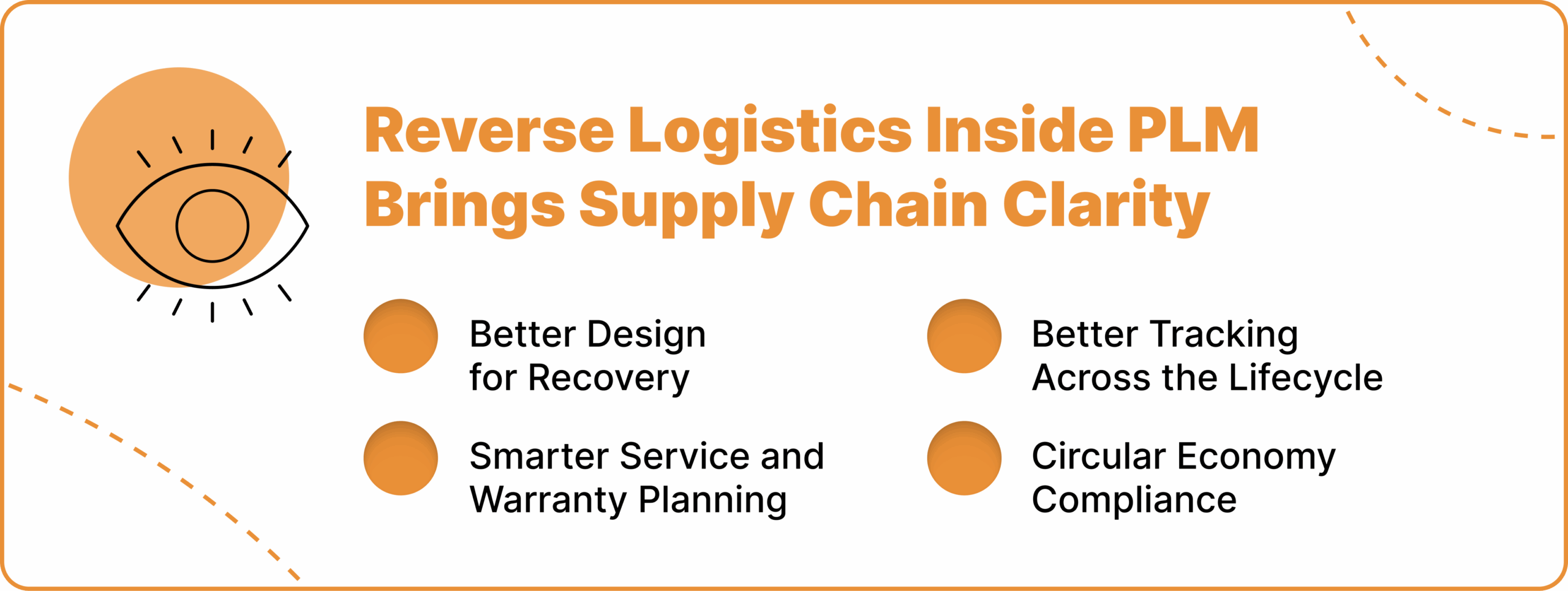

Reverse Logistics Inside PLM Brings Supply Chain Clarity

Integrating reverse logistics into PLM systems strengthens every phase of the product life cycle which allows you to lower cost of the entire supply chain, improve traceability, and support circular economy goals. Here is why:

1. Better Design for Recovery

Products that break are easier to repair when engineers design for reuse. When designed with snap-fit panels, modular parts, or removable components, these products are easier to disassemble and recover. However, such a shift begins with linking the PLM software to your returns management system. This way, your designers can plan for the product’s second life, not just the first sale.

2. Smarter Service and Warranty Planning

The current market has made it so that reverse logistics and returns management process are inevitable. Even in-store returns are rising. Now imagine a scenario where your repair department knows which parts of the products break most often, how they are used, and the most likely condition to expect the product to return to them.

With such product returns data, the returns management will improve significantly because a repair-ready product costs less to support. But that information belongs in the product life cycle management, not just in tech support tickets.

3. Better Tracking Across the Lifecycle

Reverse logistics refers not only to managing the returns of goods into the supply chain, it also entails knowing where they’ve been. Lifecycle-aware tracking lets you see which items were refurbished, recycled, or discarded—and why.

4. Circular Economy Compliance

Governments now demand proper recycling and product take-back. PLM systems integrated with reverse logistics operations help companies meet these mandates through proper planning, rather than just panicking about the mandates. When you design with recovery in mind, every part of your integrated supply chain moves faster, smoother, and cleaner.

Reverse Logistics Data Improves PLM Design

Every product return tells a story. Every item that comes back teaches you something about the product and process. When you connect your returns management data to your PLM tools, you turn returns into a design engine. This way you can:

- Discover Breakage Patterns.

If 30% of all returns are due to one faulty weld, your design team can take action.

- Learn From Real-World Use.

Customers use products in unexpected ways. But with reverse data, you have access to vital information such as wear, tear, and misuse. That’s valuable input during your detailed design stage.

- Reduce Waste Through Smarter Changes.

By mapping returned components to engineering changes, you reduce raw materials use and extend the useful life.

Reverse Logistics Enables a Real Supply Chain Loop When Integrated

A closed-loop supply chain isn’t just good for the planet. It saves money, meets customer expectations for sustainable practice, prevents delivery refusal, and reduces waste during the handling process.

Integrating the reverse logistics with the product life cycle management allows for early planning that builds a chain that works both ways. Here is why:

Forward and Reverse Flow Uses The Same Tools

Your warehouse management system can receive, route, and restock return-ready items when the product is traceable and pre-tagged for the reverse flow.

Vertical and Horizontal Integration Succeed

When your suppliers, return centers, and engineering team see the same product flow in your software system, they can share parts, cut delays, and protect quality.

Handle Regulations More Efficiently

Return-to-retail laws, recycling mandates, and disposal rules are easier to meet when your business processes include end-of-life recovery planning.

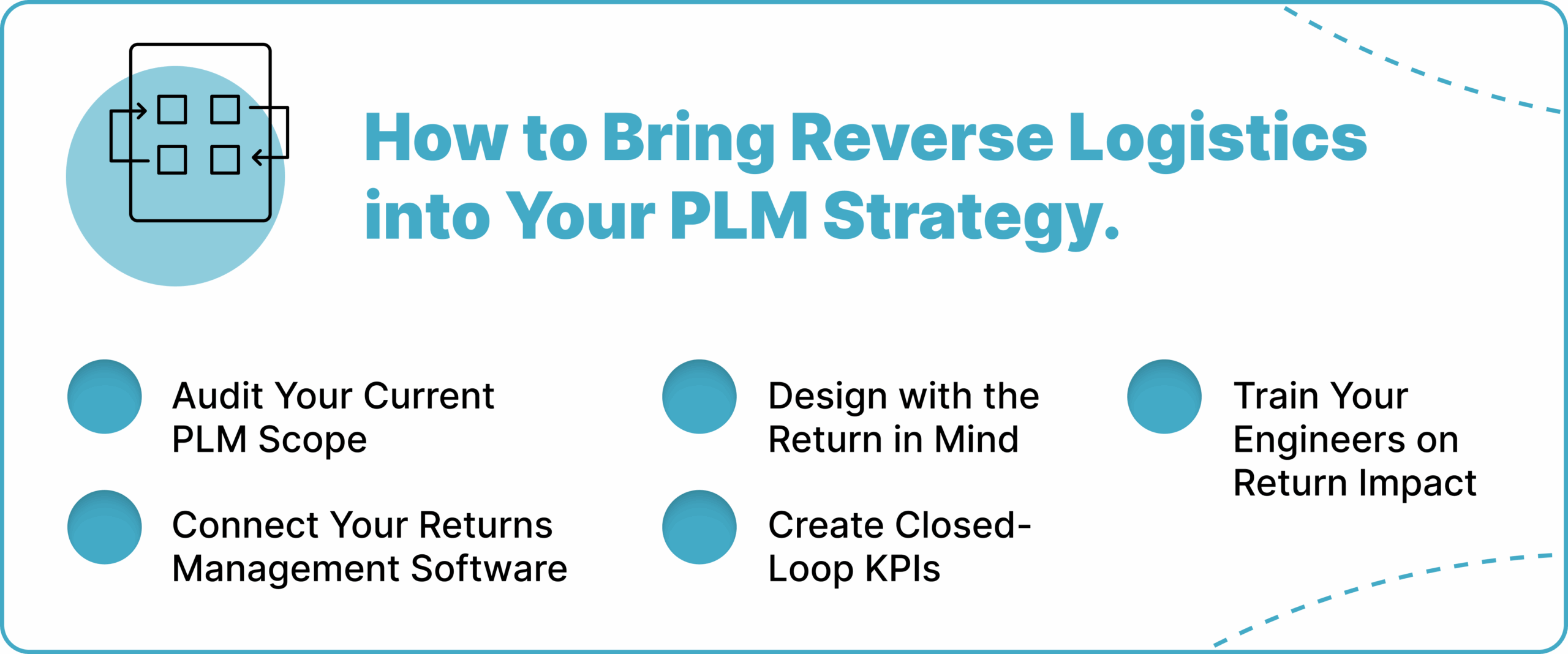

How to Bring Reverse Logistics into Your PLM Strategy

Integrating the reverse logistics with the product life cycle management makes recovery efficient and measurable, instead of a scramble. But there has to be action rather than theorizing the concept. Here is how manufacturers can bring reverse logistics into PLM technology in practical steps.

1. Audit Your Current PLM Scope

Check if your PLM system includes return data, service history, or recovery plans. If not, map out the missing links.

2. Connect Your Returns Management Software

Choose an RMS that links directly to PLM. Make sure it can handle serialized tracking, product condition logging, and rule-based workflows.

3. Design with the Return in Mind

During the design process, include return-path planning. Ask:

- Can this part be reused?

- Is it easy to repair?

- Will field techs know how to handle it?

4. Create Closed-Loop KPIs

Start tracking but don’t just focus on the refund speed. Measure recovery rate, component reuse, and repair success. These metrics protect long-term value.

5. Train Your Engineers on Return Impact

Demonstrate to design teams how product choices impact reverse logistics costs, warehouse operations, and inventory management. Make it a core part of the product development process and training. Reverse logistics works when it’s seen as a design goal, not a cost center.

Closing the Loop Boosts Profits and Loyalty

Manufacturers focused on customer demand must think about the full product journey, not just delivery. In 2025, returns are part of that journey. So are repair, resale, and recycling.

Reverse logistics isn’t just about picking up broken items. It’s about product design that makes returns useful, logistics management that keeps parts moving, and business strategy that cuts waste before it happens.

Every return you manage well creates another sale, every item you recover lowers your spend, and every component you reuse builds customer loyalty.

Build From the Start With ReverseLogix

Reverse logistics should never be a bolt-on. It should be a building block. If your systems are ready, your teams are trained, and your data is connected, you can recover more, reuse better, and reduce costs across the full product lifecycle.

ReverseLogix is the only end-to-end return management system that lets you initiate returns, configure return processing, and even handle repairs. By bringing it into your product life cycle management early, make your supply chain much more flexible and robust. The companies that win tomorrow are designing for the return—today. Get a demo today.

Frequently Asked Questions (FAQ)

Artificial intelligence helps detect return trends, predict part failures, and optimize recovery routing. When paired with PLM systems, it improves design decisions and automates the return process based on real-world usage patterns.

Machine learning identifies recurring product issues and matches them with recommended design changes. It can also support dynamic order distribution based on return rates, helping reduce waste and boost warehouse accuracy.

Poor sales increase return volume and pressure reverse flows. Without early planning, this leads to excessive inventory and missed recovery opportunities. A solid reverse logistics plan tied to PLM helps prevent overproduction and manages end-of-life decisions better.

Reusable packaging improves recovery rates and reduces shipping waste. When considered in the PLM phase, it allows for easier repair department handling and supports sustainable practices across the chain.

Engineering changes are often based on patterns found during returns. Linking the return process to CAD data and engineering workflows ensures updates are timely and based on accurate product performance data.