2023 Buyer’s Guide: Returns Management Software

Introduction

The supply chain is a web of processes, technologies, and people that orchestrate the creation and delivery of a product to a buyer. When that product comes back – which is happening more frequently – reverse logistics processes are triggered. Reverse logistics are all the steps that are triggered during a return, starting with the customer’s actions, through the shipping and transportation, in-take processes and financial mechanisms.

An especially large part of reverse logistics is getting more attention in recent years: Returns management. Returns management is the critical part that includes the processes, people and technologies required for a seller to manage a product that is returned.

Why are Companies Prioritizing Returns Management?

– eCommerce product return rates are about 16.5% (NRF)

– Between 22% and 25% of survey respondents admit to some form of returns fraud (Signifyd)

– The 2022 holiday season saw a 63% increase in returns YOY (Salesforce)

Returns management: A new category in supply chain software

With the rise in buying and selling trends, such as free shipping and huge growth in eCommerce sales, the volume of product returns for both B2C and B2B companies has steadily increased in recent years (with especially big jumps during the COVID pandemic).

Companies have spent many years and millions of dollars optimizing the transportation, warehousing and order management aspects of their supply chain. Now is the time to focus on returns management.

Returns management is a relatively new category of supply chain management software, but it’s a “must have” for enterprises that want to efficiently manage, orchestrate, and track product return activities.

Returns management software can manage:

- How a customer (a consumer or a business) initiates the return

- The steps and processes within a store, warehouse or DC that happen when a product is returned

- Customer communication about the return

- The reporting and business intelligence that reveals insights into return trends, issues and operations

Returns management system (RMS): A closer look

A returns management system (RMS) is a specific software solution that enables companies to streamline return requests, logistics, inventory and processing. An RMS connects every point and every step of a product return, from start to finish. It offers B2C, B2B and hybrid sellers a total, end-to-end solution to returns management.

An RMS is the final piece of a comprehensive supply chain software suite. It delivers two major functions:

- An RMS fully manages the entire, end-to-end returns process according to an organization’s specific needs.

An RMS manages everything that goes into the returns process: returns processing, repairs, return-to-vendor, customer portals, RMA initiation, and customer notifications. An RMS can be configured to unique processes and requirements – or a customer’s – to drive an efficient returns process, standardized tasks and improved accuracy.

- An RMS centralizes and analyzes returns-related data from other, core supply chain software.

Because an RMS tightly integrates with technologies such as WMS, OMS and TMS, it can reveal new, actionable data about returns. Data, business intelligence, reports and more…no more point solutions!

Returns Management Software Use Cases

Clustered, inefficient returns management has threatened to overwhelm companies with cost, waste and complexity. Companies across industries are taking a hard look at streamlining, automating and reducing the cost of returns processing.

Whether you have B2C, B2B, hybrid, or 3PL operations, an RMS can transform your returns management processes.

RMS use cases: B2B companies

B2B buyers now expect the same level of speed, ease, and autonomy when making a business return as they do when returning a personal item. But unlike exclusively consumer-facing companies, B2B enterprises have added complexity with their product returns:

- Managing multiple returns and claim types from partners

- Rules and policy management for partners

- Warranties and repairs

An RMS purpose-built for B2B companies will address these issues and more.

- Automatically receive returned items and data in standardized formats

- Absorb returns data from many different partners— automatically

- Reveal visibility into a company’s warranty claim management, dealer returns, and repair network.

- When items arrive at your facilities or authorized service centers, the RMS can automatically process those returns.

- Dealer warranty claims management enables dealer networks to initiate returns and handle entitlements, rules, and claims based on your requirements.

- Dealer Network Repair Management ensures everyone is handling repairs and parts management in a standardized way based on your rules.

- Failure analysis for parts and products that have been returned.

- End-to-end network visibility that gives full visibility into returns and repairs, down to the individual SKU.

B2B Returns Management Resources

– 6 Reasons B2B Companies need Returns Management Software

– ROI Calculator

– On-Demand Webinar: How to Create a Seamless B2B Returns Process

RMS use cases: B2C companies

An RMS streamlines and automates every step of the B2C returns process, from the RMA to final credit or refund. A fast and easy returns process is essential: Customer loyalty depends on it. Your profitability depends on it. Your operations depend on it. Your corporate sustainability goals may even depend on it.

An RMS orchestrates an exceptional returns process and experience for customers and your employees.

- Prioritize customer convenience with return options they’ll appreciate: Drop-off locations, box-less returns with QR code, sustainable options, etc.

- Configurable workflows drive a faster returns process, standardize tasks and improve accuracy

- Set up rules and policies to incentivize exchanges over refunds, retain revenue, and keep customers coming back.

- Speed up returns processing by automatically approving, rejecting, or flagging returns and exchanges for review based on conditions you set.

- Centralize/analyze returns-related data to inform the purchase experience and create happier customers who ultimately keep more of their purchases

B2C Returns Management Resources

– Choosing an RMS: 5 Factors

– ROI Calculator

– How a Global Retailer Solved Complex B2C Returns Processing

RMS use cases: 3PLs

3PLs are perfectly positioned to take over returns management for customers. As the trusted partner for managing fulfillment, 3PLs can provide enhanced value with returns services across the mix of SKUs already moving through the facility.

- Provide a valuable service for customers

- Add an entirely new revenue stream

- Differentiate yourself in a commoditized industry

- Break into new markets with an offering that attracts new accounts and expands business

“By offering returns management to an existing customer base, we’ve seen 3PL customers increase revenues 10%-30%.”

Gaurav Saran, CEO, ReverseLogix

3PL Returns Management Resources

– Making Returns Profitable: A Playbook for a new 3PL Opportunity

– ROI Calculator

– 3 Reasons 3PLs are Adding Returns Management Services

Key Benefits of an RMS

If not managed efficiently, product returns can be a headache for your operations, frustrating for your customers, and a drain on your bottom line. With an RMS, you can save, streamline and simplify.

Reduce costs

An RMS can be implemented quickly, so you get a fast ROI and a near-immediate impact on cost efficiency.

- Automate and free-up employees for more revenue-driving tasks

- See real-time data on the costs of receiving, handling, repairing, replacing and shipping an item

- Process returns faster and set rules for restock, so you get the most value out of returns

Improve operational efficiency

No need for a patchwork of systems! An RMS is the single, end-to-end solution for returns management. It integrates into your tech stack for total and immediate returns visibility.

- Improve items or brands that have high rates of return abuse or fraud

- Increase tracking visibility and processing transparency

- Create and automate rules that streamline or throttle returns decisions, enforcing policies consistently across a network

“The time required for processing a return is one-fifth the time it took before ReverseLogix returns management technology.”

Leif Revere, director of distribution center systems, Genesco

An exceptional customer experience

Whether your customers are B2C or B2B, they want a smooth and fast returns experience. An RMS delivers that and more, with rules and exceptions that you can configure to give the best experience, every time.

- Self-service customer portal for easy, intuitive returns

- Automated notifications keep customers informed and lessen the burden on customer service teams

- Create rules and exceptions that give priority customers an immediate refund or credit.

Improve compliance and sustainability efforts

Brands are making public commitments to improve sustainability across the entire supply chain, including returns. An RMS helps avoid unnecessary waste, transportation emissions and material consumption. Its BI and insights can even help you reduce overall returns volume.

- Avoid transportation costs and mileage by tracking the impact of consolidating products and vendors shipments

- Set priorities and rules around repairs, refurbishing, recycling and disposal

- Incentivize local return locations to minimize emissions and gain higher resale probability based on seasonality and demographics

“With reports about reason coding, we’re getting better control over the process and what needs to be improved to reduce the amount of returns in general.”

Kai Bahlman, vice president of warehousing, Amer Sports

Enhance data visibility and insights

The power of an RMS is the quality of its returns data, centralizing and analyzing information from your core supply chain systems.

- Get a better handle on opportunities for improving efficiencies by measuring average time to process RMAs, per-item handling costs, and disposition cycle times.

- Benchmark returns efforts with sustainability goals, with KPIs like returned merchandise resale percentage or distance traveled per returned item.

- Discover your true returns costs with metrics such as total product costs, returned item rates and inventory. RMAs by channel help you track returns from stores, online, wholesale locations.

“We have really robust reporting that’s relevant to many teams throughout the company. The credit team uses ReverseLogix for reporting; the customer service team relies on it to see whether returns have been processed; even our manager who oversees our 3PL partner uses ReverseLogix for insight.”

Director of Distribution Operations for Global Retailer

RMS Features to Consider

Returns management systems vary by features, the environments in which they operate (B2C vs B2B vs both), and the data insights they can deliver. These are the top features to consider when you are examining RMS vendors.

End-to-end returns management

An RMS should manage and orchestrate the entire lifecycle of a return, from start to finish. No need for point systems or a patch work of software: One RMS should have the power and visibility to manage it all.

- The customer experience: Return portals, RMAs and notifications

- Configurable workflows: Set rules and standards for your needs, or adjust them by location or product type

- Returns processing: Receiving, inspection, grading, put-away, discrepancy, approvals, tracking, reject codes, multi-role and multi-location

- Order tracking: Carrier integrations with visibility into how many returns are expected at the warehouse and when, along with timely customer notifications.

Reporting and analytics

One of the biggest values of an RMS is the data and insight it delivers. Finally, you gain visibility into your returns costs, transparency into your processes, and the actionable insight to improve.

- Customized reporting based on departments, user roles or locations so distributed teams always stay in sync.

- Metrics in every module, queue and order.

- Essential metrics that help you determine per-item handling costs and total product cost that includes COGS, initial shipping, returns processing, return shipping, marketing, and disposition minus what you can get for resale or disposal.

Real-time tracking and monitoring

Return shipment capabilities and forward tracking of order shipments should go hand-in-hand. By eliminating separate shipping and tracking systems, you gain analytics and functionality for easily capturing and reviewing orders, shipment performance information and consumer feedback in a single interface.

- Customers get on-demand tracking and communications right on your site, including automated updates at each stage of the returns process

- You can see which returns are coming in, how many, and which locations so that you can staff up appropriately.

- Forward tracking capabilities provide complete visibility of shipping activity in a centralized location.

Scalability

An RMS can be applied to diverse locations – stores, warehouses, microfulfillment centers, DCs, partner locations and 3PL facilities – around the world. Its flexibility and configurability enables you to scale quickly and shift to meet market needs.

- Task and decision automation means fewer resources are needed to manage returns, freeing up employees for other important work

- Automate customer notifications to reduce call volume and “Where’s my refund/exchange?” inquiries

- Leverage RMS technology to verify purchases and approve returns, thereby reducing fraud risk

“I can plan my manpower for the day or week, because all I need to do is look on ReverseLogix and it’ll tell me how many returns we’re expecting between my two different areas of returns.”

Erin Johnson, Senior Returns and Vendor Compliance Manager, Genesco

Tight integration with other systems

An RMS can integrate with other supply chain software like WMS, TMS, ERP and OMS. It should also offer integrations with sales, POS and logistics platforms, such as Shopify, WooCommerce, DHL and FedEx.

- Spend less time managing the returns ecosystem

- By integrating with third-party systems, the RMS can pull data from each phase of the returns process and present a complete picture of costs, timing and opportunities for improvements.

- Look for an RMS with open APIs that drive faster implementations and faster ROI

Refurbishment and recycling management

The rise in return rates are feeding concerns about the waste, emissions, and how those returns are disposed. An RMS’ data analytics can reveal how to align your returns processes with corporate sustainability priorities.

- Set rules for restock based on geography or seasonality, so you can get the most out of returns

- Incentivize customers to use return locations that minimize emissions and have higher resale probability based on seasonality and demographics.

- Set disposition rules based on demand, sustainability goals, processing costs and sell-through rates.

- Understand recovery costs and how to connect returned inventory to the right channels (including third-party marketplace sites) to reduce environmental impact.

B2C, B2B and hybrid environments

Most RMS technology serves B2C enterprises. But as the lines between B2C and B2B blur – and as B2B customers come to expect a consumer-like shopping experience – the ability to offer the same intuitive features becomes even more important.

- Look for an RMS that offers portals, rules, and flexibility to serve any environment

- Set rules, policies and exceptions for certain dealers, distributors or item categories

- Faster times to process returns, fewer employee touch points, and better standardization that catches fraudulent returns

Tracking Returns Management Metrics

Do you know your average return rate by category or SKU? Do you know your average cost for processing a return and what your true margins are?

Most companies don’t know these stats. According to Gartner, fewer than one-third of retailers say they have visibility of all related returns management costs when it comes to loss in inventory value in storage.

Why are returns management metrics important?

Without good data, you can’t know what to improve, where the waste is, how to measure success, or even what to measure in the first place. Until recently, the lack of returns-specific technologies made metrics hard to find, aggregate and act upon.

But today, with an RMS, companies can get a full picture of your returns costs. An RMS is the only supply chain management software that has the full picture of your returns lifecycle.

Which returns management metrics should I monitor?

Companies with an RMS can view every module, queue and order. Every screen offers data and business intelligence. Reporting should be automated when possible and customizable when needed, so you get immediate insight to make sure your goals are on track and that you’re catching problems early.

Key metrics for process improvements

- Average time to process RMAs/average time by RMA task: Track the returned item from the time a customer requests the return until the final disposition (exchange, resale, RTV, recycling, repair or disposal). This metric is helpful for spotlighting areas of your operations that are doing well or that need an efficiency boost.

- Per-item handling costs: What is the total cost to process returned items, taking into account facility costs, labor costs, shipping costs, etc.? If you have multiple facilities that process returns, this metric can be a comparison tool that helps remove bottlenecks and automate processes that don’t need a human touch point.

- Disposition cycle time: How quickly can you get products from the return stage to the proper disposition? Track this metric separately for items that can be resold, returned to vendor, recycled, or thrown away – that way, you can compare how much time each one takes.

Key metrics for sustainability initiatives

- Recycled product vs waste: How much material is appropriately recycled? How much of it is thrown away? These are important metrics for sustainability efforts that prioritize reselling or recycling rather than landfilling.

- Returned merchandise resale percentage: Figure out how much of your returned product can be resold. This is important both for recuperating costs and for sustainability goals. You’ll also be able to see how much of the initial sales price you can recapture.

- Distance traveled per returned item: Consumers love online shopping, but the back-and-forth delivery eats up packaging materials and drives up vehicle emissions. “Distance traveled” metrics can be broken down by disposition type, such as resale, recycling, return to vendor, and landfill waste.

Key metrics for productivity and cost

- Total product costs: To get a true sense of cost, you need a metric that includes COGS, initial shipping, returns processing, return shipping, and disposition costs minus any money you can get for resale or disposal (such as RTV).

- RMAs by channel: Track returns from retail, eCommerce, wholesale, and more to gain better visibility into costs, speed and productivity by channel.

- Returned items inventory: Which items are returned at what rates? Uncover the items that are more likely to be returned and any common reason codes, so you can pinpoint root causes and make processing the return more efficient.

RMS vs Point Systems

Point systems like an ERP or WMS can capture a snapshot of a return during its journey, but it’s not the full picture. An RMS that can tightly integrate with other supply chain software gives you one system, one platform, and one centralized location of returns data, from start to finish.

RMS Vendor Selection

RMS vendors vary by experience, support, industries they serve and the tech features.

- Experience: Look for a vendor that has served big-name brands for an extended period of time, and that has a track record of responding to customer returns needs with innovative approaches.

- Support: A vendor should have a variety of support teams that can be contacted 24/7 by email, text, phone or chat. For global vendors, ask about their services in a variety of languages.

- Industries: Few RMS vendors serve both B2C and B2B environments, or a hybrid of the two. If this is important to you, be sure to ask about this up front.

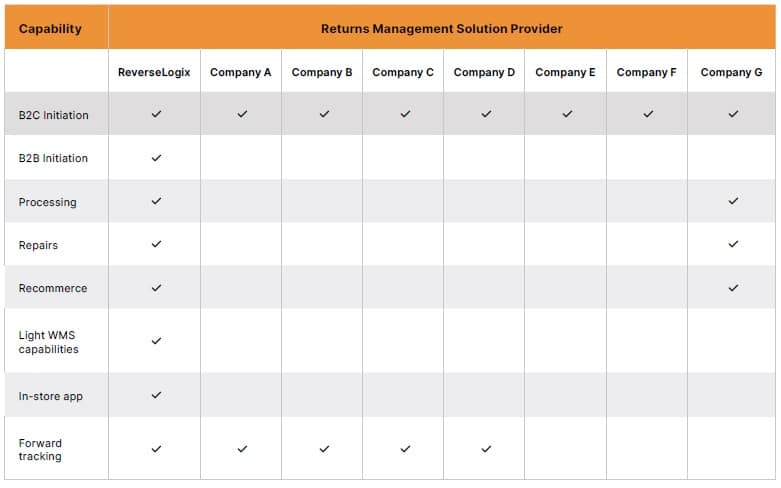

RMS Technology Features: Comparison Chart of Real-World Vendors (anonymized)

Integrations and Upgrades

An RMS should be able to integrate with your WMS, OMS, TMS, ERP, and other major supply chain software solutions. In addition, look for out-of-the-box integrations (like these) so you can spend less time managing ecosystems!

- Shopify

- Salesforce

- Magento

- NetSuite

- Oracle

- WooCommerce

- FedEx

- SAP

As a SaaS solution, upgrades will be automatically handled by your vendor. As your other supply chain systems upgrade, ask potential vendors about how the RMS will update and stay in sync.

Conclusion

Finally, a purpose-built supply chain software system exists that can manage and automate the entire returns process: a returns management software. Companies are unlocking new ways to process returns faster, avoid returns altogether, save costs, and make customers even happier.

We hope this Buyer’s Guide for returns management software enables you to confidently review and select the best RMS for your company and your customers.

Helpful Resources for Choosing an RMS

– Get a Demo of ReverseLogix

– Everything you Need to Know about an RMS

– ReverseLogix ROI Calculator

– Explore Chat GPT’s information on returns management compared to ReverseLogix

– Choosing a Returns Management System: 5 Factors