How Returns Processing Management Improves Business Profitability

As e-commerce continues to dominate the retail industry, return options are necessary to survive the competitive landscape. However, beyond offering returns for customers, these platforms also have to streamline and optimize the returns processing to ensure customer satisfaction and profitability of the entire operation. Failure to do that can turn a competitive edge into a financial drain for the business.

Effectively managing and running return processing can transform product returns. It doesn’t have to be the soft underbelly of the supply chain process that managers shy away from. When done well, it can boost overall operations, turning it into a strength for any business, especially e-commerce brands. To achieve that, there has to be a thorough understanding of the infrastructures that make for successful return processing.

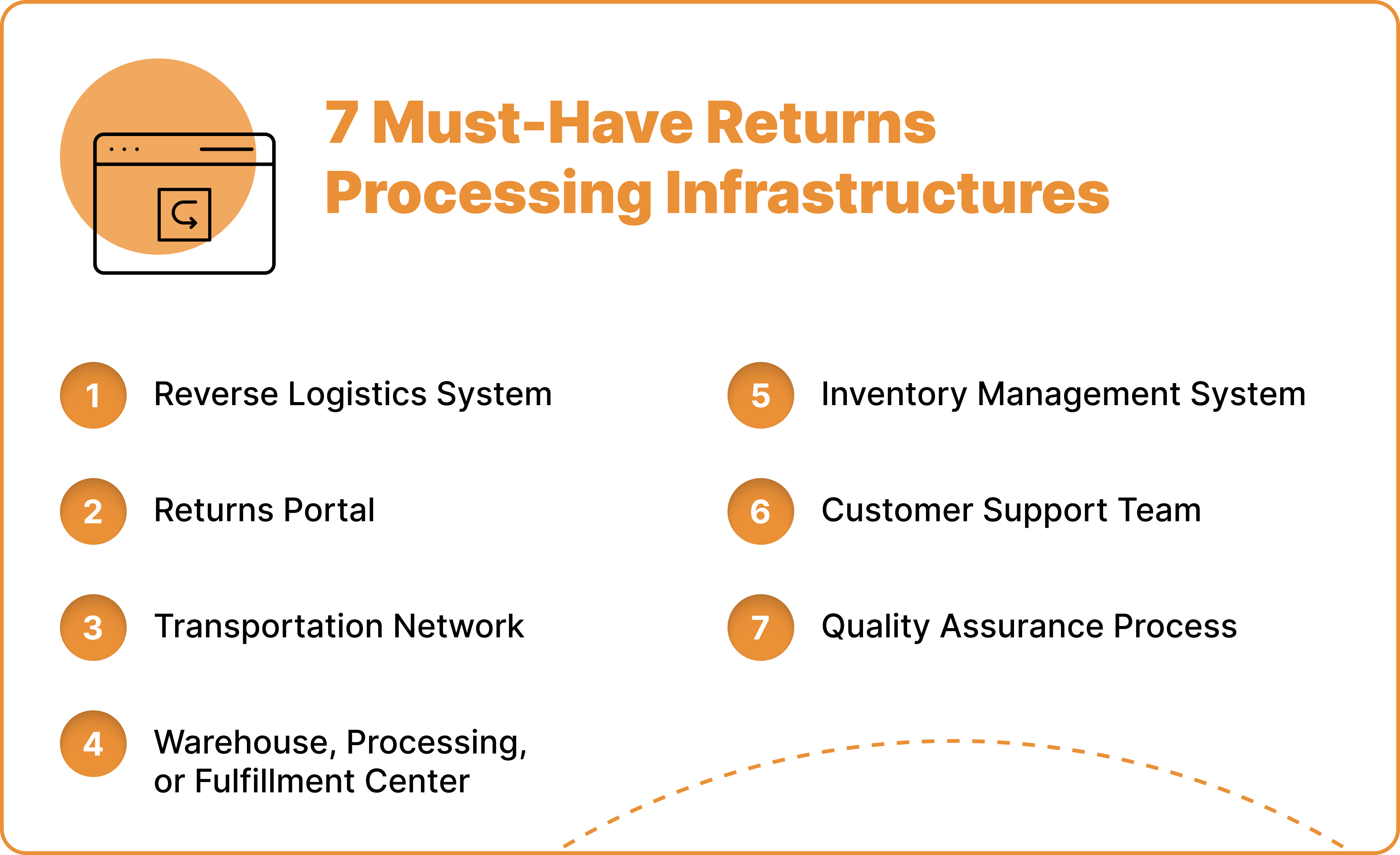

This article discusses the seven essential infrastructures that any business must have in place before it can effectively handle the returns process, build customer loyalty and trust, and enhance operations across the board.

1. Reverse Logistics System

While products are typically moved from the business or supply chain management to the customer, it is now common to see products making a round trip, moving back from the customer to the business. Reverse logistics refers to the flow of product or inventory from the customer back to the business through various options, including pick-up, store drop-off, or a third-party delivery process. The process plays a significant role in managing returns but comes with unique challenges.

Some of these include handling unpredictable volumes and ensuring products are returned promptly and efficiently. There is also the problem of cost. While order-to-delivery costs are packed into operational costs when calculating product margins, the whole process following a product return is not well accounted for.

Product returns are an unwanted or unplanned financial burden. This makes having a solid reverse logistics plan, supported by tech solutions for greater efficiency and a standardized approach, essential for effective reverse logistics management. Ecommerce businesses must prioritize the above to enjoy efficient reverse logistics processes. These processes will also help minimize costs while maximizing the recovery value of the returned goods.

2. Returns Portal

The sheer volume of modern returns has overwhelmed traditional methods, making return portals a crucial solution. They empower customers to initiate the returns process and choose from various return options, allowing them to manage returns seamlessly from anywhere without the hassle of time-consuming tasks like calling customer service.

Beyond allowing customers to initiate the returns process, the portal also serves as a communication channel, informing customers of every step of the returns process. Customers can view pick-up schedules, delivery vehicles, driver details, and track the status of their returned goods even after they reach the sorting and processing facilities. This fosters transparency and customer satisfaction in the return process or system, ensuring they are more comfortable with the business or store.

A well-designed returns portal also provides businesses with valuable data on why products are being returned, enabling continuous improvement in product quality and customer service.

3. Transportation Network

Returns must be transported back to the business or supply chain, and the process must be managed effectively through a network. This could be done by leveraging an in-house fleet or relying on third-party carriers. Whatever the case, the ultimate goal should be to ensure a smooth and cost-effective returns process for the customer and the business.

However, managing these transportation networks effectively is challenging without the right tech solutions. Tools like route optimization and GPS are essential for streamlining operations, identifying the fastest routes, and enhancing transparency across the entire process. Businesses in the returns process need a reliable and flexible network to ensure that goods are returned to fulfillment centers or warehouses with minimal delays, keeping customers satisfied and inventory moving.

4. Warehouse, Processing, or Fulfillment Center

Returns processing typically involves inspections, sorting, discarding (waste management), restoring, repairing, reintegration into inventory management, packaging management, and/or shipping the same goods back to the consumer. These processes require a well-structured facility, allowing the business to manage them more efficiently and have more control over the process. That way, operations are more streamlined, and customers are better informed about the entire process.

The purpose of the warehouse or the processing facility is one thing, but to get the most out of it, the business or supply chain needs to ensure the following: strategic location, adequate staffing, and proper technology solutions. They will help reduce the burden on the main warehouse, preventing disruptions in fulfilling new orders.

5. Inventory Management System

The inventory management system enhances businesses’ and supply chains’ ability to have more control over the flow of their inventory, whether it is coming or going. When a business accepts returns, it can get complicated, especially because customers often favor that option. However, the main issue is integrating those returned products into the system, where the inventory management system (IMS) plays a significant role.

With this system, businesses can monitor inventory in real-time, ensuring returned items are restocked promptly or routed for repairs. Additionally, an IMS can help identify trends in returns, providing actionable data that can improve future product offerings and reduce returns in the long term.

6. Customer Support Team

Although customers are comfortable with businesses that offer returns, there is also a lot of tension during the actual return process, causing them to inquire more about the returned products or the business’s decision-making policy. It can be quite a lot to manage, especially considering the business is also under pressure to ensure efficient returns processing and operations.

This is why well-trained and knowledgeable customer support teams are necessary. Whether assisting customers with return requests or resolving refund-related issues, the customer support team plays a vital role in ensuring a positive experience. As much as sales and efficiency are great, a poorly run customer support team can damage the business’s reputation and eventually turn customers away.

7. Quality Assurance Process

A quality assurance process is a critical system that allows for adequate and efficient evaluation of the condition of returned goods. Returned items must be thoroughly inspected and graded to determine the best decision regarding that product. It could be resold, repaired, or written off. Businesses should establish clear guidelines for assessing returned products, including creating specific categories for different conditions. Proper sorting and grading ensure that quality standards are upheld and allow businesses to maximize the value of returned items.

Set Up The Right Returns Processing Infrastructure With ReverseLogix

ReverseLogix is the only end-to-end return management system that lets you initiate returns, configure return processing, and handle repairs. With this platform, you can create efficiencies and increase productivity in your returns management operations.

Returns processing can be complicated, but only without the right partner. ReverseLogix offers solutions such as automation, fraud prevention, and improved customer experience, allowing for a seamless return process. Get a free demo today.

Frequently Asked Questions

A good returns portal should offer easy return initiation, label printing, and tracking capabilities. It should also allow customers to choose their preferred return method (such as pick-up or drop-off) and keep them informed about the status of their return at every step.

Businesses can reduce reverse logistics costs by optimizing transportation routes, automating return processes, and using efficient warehousing solutions. Proper planning, such as offering centralized return points and using third-party logistics partners, can also help minimize expenses.

Technologies such as route optimization tools, inventory management systems, and automated return portals streamline the reverse logistics processes and communication with supply chain partners. These solutions improve visibility, reduce processing times, and provide real-time updates to both customers and the business, making returns more efficient and cost-effective.