Study Reveals Retailers' Biggest Returns Costs

A busy holiday shopping season just got busier, as retailers now face record-breaking product returns and scramble to minimize return costs.

Many chains extended their return policies in an effort to lure in holiday shoppers early in the season, boosting the timeframe from the typical 30 days to 60 or even 90 days. That, along with supply chain concerns, were some of the big factors that motivated shoppers to buy sooner. But it also helped trigger a tsunami of returns that are flowing back in.

According to Reuters, U.S. shoppers are expected to return a record $112 billion to $114 billion worth of merchandise in the coming weeks, which is a 24%-27% increase over 2019 post-holiday returns. Furthermore…

Retailers do not usually break out return rates or related expenses, but signs are emerging that the wave of returns started much before Christmas this year as consumers started shopping sooner, leading to higher costs because of the longer grace period, according to some retailers.

This is adding stress to reverse logistics; the part of the supply chain that has long been overlooked and lags behind other areas in terms of efficiency improvements or optimization solutions.

“For most retailers, the returns process is too manual and too complex to effectively scale with the increased volume of returns,” said Gaurav Saran, CEO of ReverseLogix.

Why are retail returns expensive?

In a recent ReverseLogix research study conducted with Lead to Market, 80% of retailers interviewed reported that the cost of returns to their company is “significant to severe.”

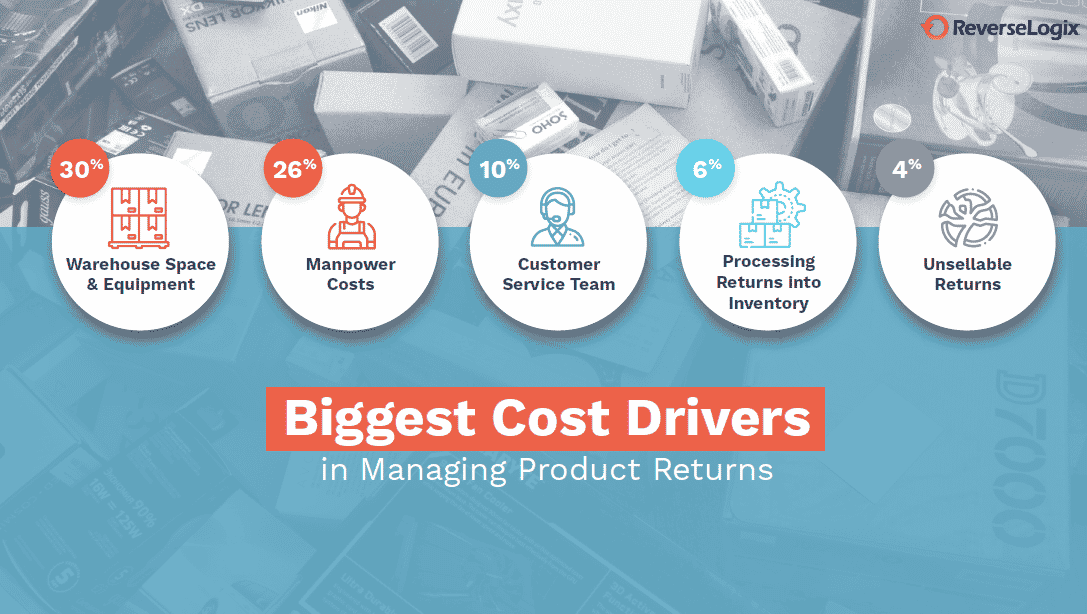

Two main culprits emerged as the biggest cost drivers when managing product returns..

- Warehouse space and equipment (30% of respondents)

- Labor costs (26% of respondents)

This frustration with high costs leads to frustration with the entire returns part of the supply chain. Seventy percent of survey respondents were dissatisfied with their company’s returns processes!

Even more revealing, respondents know what needs to be done to improve product returns. They identified…

- The need for faster refunds

- Better process automation

- The ability to support multiple return channels

But they lack the tools to make these improvements happen: More than half of respondents are trying to manage returns with an ERP or warehouse management system (WMS). Neither were built with the flexibility or structure to optimize returns management.

Minimizing return costs with an RMS

A returns management system (RMS) that’s purpose-built for retailers can efficiently manage product returns with flexibility and automation capabilities that other tools simply can’t match. An RMS facilitates, manages and reports on the entire returns lifecycle. With an implementation period of weeks (not months), it can deliver fast ROI and have a near-immediate impact on minimizing the cost of product returns.

Warehouse costs

While a WMS excels at inventory receiving, put-away, picking, replenishment and shipping, it’s not architected to handle the complexity of reverse logistics.

Even if a WMS manages a portion of the returns process “good enough,” it still forces companies to rely on other point solutions to manage other parts. Here at ReverseLogix, we’ve worked with many customers that have a Frankenstein system of mismatched solutions, none of which manage the full end-to-end returns process and all of which come with their own costs that add up fast.

In addition to managing the full returns process from beginning to end, an RMS includes self-service capabilities for customers that require less involvement from retailers, and gives retailers full, 360-degree insight into product return trends that helps track costs more accurately. Whether a return location is in a store, mailed to a warehouse or managed by a 3PL, the RMS platform ensures everyone is working off the same workflows and rules for consistency and efficiency.

Labor costs

Configured workflows in an RMS can address a retailer’s specific needs and ways of doing business – across warehouses and shipping locations. Rules and policies can be built to ensure products are accepted, inspected and dispositioned consistently, anywhere in the world. An RMS takes the guesswork out of return processes, empowering your labor force to work more efficiently and empowering managers with reporting data to catch issues or highlight improvements.

Overcoming returns obstacles

To learn more about how survey respondents are managing returns, their greatest needs and most helpful solutions, you can download our full report: Frictionless Returns: The Missing Piece of the eCommerce Experience.