Inventory Recovery: 10 Steps to Properly Recover Assets

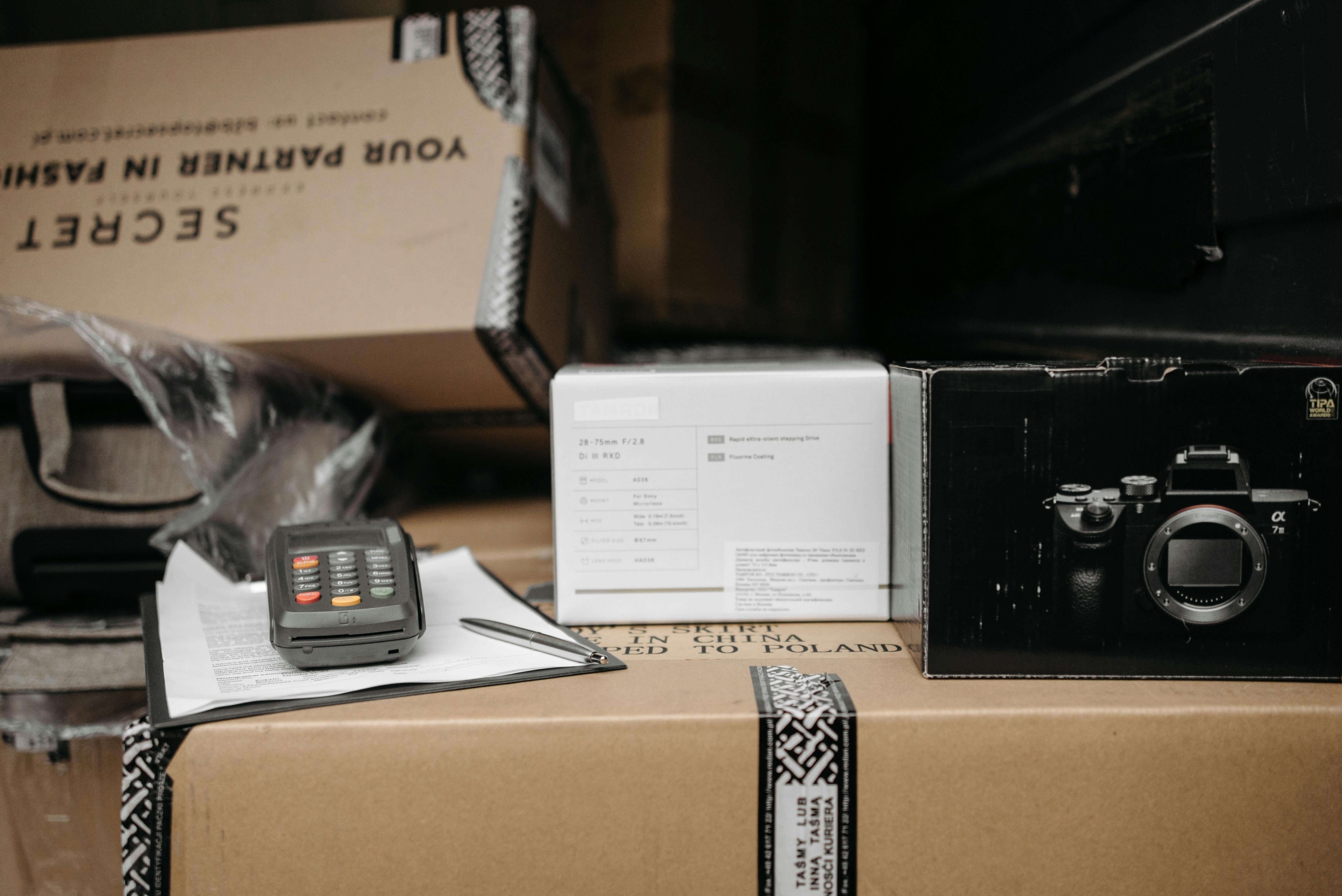

Inventory recovery helps businesses get value from extra or returned stock. Without a plan, leftover inventory can take up space and cost money. A good recovery process cuts losses and keeps the product moving as it should.

This guide covers 10 steps to recover assets correctly, from checking stock levels to using inventory recovery systems. Whether dealing with extra products, outdated items, or returns, we’ll help you find the best approach to improve inventory management and profits.

What is Inventory Recovery?

Inventory recovery is the process of reclaiming value from extra, outdated, or returned inventory. Businesses use different methods to resell, repurpose, or dispose of stock in a way that reduces waste and saves money.

Inventory Recovery Definition

Inventory recovery means finding ways to recover costs from unused or unsold products. This can include selling extra stock, recycling materials, or using liquidation channels. The goal is to reduce losses and get the most value from every item.

Many businesses use inventory recovery systems to track extra inventory and decide how to handle it. These systems help make smart, data-driven choices and improve inventory management.

Why Businesses Need Inventory Recovery

Without a recovery plan, extra inventory can become a costly problem. Overstock, product returns, and seasonal shifts can leave businesses with too much stock and nowhere to put it.

A strong inventory recovery strategy helps businesses:

- Cut losses from unsold products

- Free up space for new inventory

- Improve cash flow by selling or reusing items

- Minimize waste and support sustainability

The right approach helps businesses turn extra stock into a valuable asset instead of a burden.

Key Components of an Effective Inventory Recovery System

A strong inventory recovery system helps businesses track, manage, and reclaim value from returned inventory. Without this process, companies risk losing money on unused or outdated stock. By using data-driven methods, businesses can recover assets and improve profitability.

Tracking and Identifying Surplus Inventory

The first step in inventory recovery is knowing what you have. Businesses must track surplus stock and identify overstocked, outdated, or no longer-needed items. Regular inventory analysis helps companies spot excess products before they become liabilities.

Technology is vital to this process. Automated tracking systems, barcode scanning, and real-time reporting help businesses track inventory levels and make informed decisions.

Assessing Asset Value and Disposal Options

Not all surplus inventory has the same value. Some items can be resold at full price, while others may need to be discounted, recycled, or donated. Businesses should review product demand, condition, and market value to make the best decision.

Inventory turnover is an important metric in this process. It shows how quickly products sell and helps businesses decide which items to prioritize for recovery. Low-turnover items may require alternative strategies, such as liquidation or repurposing.

Choosing the Right Inventory Recovery Method

Once inventory is assessed, businesses must decide the best way to recover its value. Common strategies include resale, refurbishment, donation, or recycling. Strategic asset management ensures inventory recovery efforts align with financial goals and sustainability initiatives.

Combining tracking, valuation, and smart recovery methods can cut down on waste, free up space, and maximize returns.

Steps to Properly Recover Assets and Inventory

A strong inventory recovery process helps businesses lessen waste, cut costs, and get value from extra stock. These ten steps will help businesses recover assets and keep inventory under control.

Step 1: Conduct a Full Inventory Audit

The first step is knowing exactly what inventory you have. A full audit helps track extra stock, damaged goods, and slow-moving products. Businesses should check storage areas, warehouses, and digital records to get a clear picture of their inventory.

Barcode scanners or inventory software can make this process faster and more accurate. A detailed audit allows businesses to plan how to recover value from their extra stock.

Step 2: Classify and Categorize Inventory

After the audit, businesses need to sort inventory into groups. Doing so helps decide what can be sold, repaired, donated, or recycled. Common categories include:

- New or unused products – Items that can be sold at full price

- Refurbished goods – Products with minor damage that can be fixed and resold

- Obsolete stock – Outdated items that may need to be discounted or recycled

Step 3: Determine the Best Recovery Strategy

Not all extra inventory can be handled the same way. Businesses should choose the best method based on product condition, demand, and company goals. Options include:

- Selling extra stock at a discount

- Repairing and reselling damaged items

- Donating products for tax benefits

- Recycling or disposing of unsellable goods

Choosing the right recovery strategy helps businesses reduce losses and get the most value from their inventory.

Step 4: Leverage Inventory Recovery Systems

Technology can make inventory recovery easier and more efficient. Inventory recovery systems help track extra stock, analyze demand, and automate decisions. These tools provide real-time data on inventory so businesses can act quickly. Automated systems also reduce errors and speed up the recovery process.

Step 5: Optimize Logistics for Maximum Return

Once businesses decide what to do with their extra inventory, they need a plan to move it. A strong logistics strategy ensures products are stored, transported, and delivered efficiently.

Good order management helps track shipments, avoid delays, and reduce costs. Whether shipping to customers, warehouses, or liquidation partners, an organized system ensures everything gets where it needs to go.

Step 6: Monitor and Improve Recovery Processes

Inventory recovery is not a one-time task. Businesses should regularly review their process and look for ways to improve. Key performance indicators (KPIs) like inventory turnover rates, recovery costs, and sales data help measure success.

Tracking these numbers helps businesses adjust their strategies to recover more value over time.

Step 7: Establish Vendor & Partner Relationships

Working with the right partners makes inventory recovery easier. Liquidators, wholesalers, and recycling companies can help businesses move extra stock faster. Strong relationships provide more options for selling or disposing of inventory.

Reliable vendors also offer better pricing and consistent service, making the recovery process seamless and more profitable.

Step 8: Implement Data-Driven Decision-Making

Businesses should use data to guide their inventory recovery efforts. Tracking sales trends, demand, and storage costs helps companies make smarter decisions.

Predictive analytics and AI tools can help businesses determine the best time to sell, discount, or recycle inventory. Relying on data instead of guesswork leads to better recovery results.

Step 9: Ensure Regulatory Compliance & Documentation

Selling, recycling, or disposing of inventory must follow industry rules and legal requirements. Businesses must stay updated on tax laws, environmental regulations, and resale policies.

Keeping detailed records of recovered inventory and transactions ensures compliance and protects businesses from fines or legal issues. Proper documentation also helps track financial performance and tax benefits.

Step 10: Train Staff on Best Inventory Recovery Practices

Employees play a big role in inventory recovery. Businesses should train staff to track, sort, and recover inventory properly. Well-trained employees can:

- Identify extra stock that can be resold or repurposed

- Follow company policies for handling surplus inventory

- Use inventory systems to keep records accurate

Regular training keeps teams updated on best practices. Employees who understand how inventory recovery works help businesses recover more value and reduce waste.

Common Challenges in Inventory Recovery & How to Overcome Them

Recovering inventory isn’t always easy. One big challenge is handling product returns. Without a clear returns management process, businesses may struggle to resell or recycle returned items. A good system helps track returns and prevents losses.

Another issue is poor inventory tracking. If businesses don’t know what they have, they may keep extra stock so long that it loses its value. Digital tracking tools help businesses act fast and recover inventory before it becomes useless.

Finding buyers or disposal options is also difficult. Partnering with liquidators, recyclers, or secondary market buyers helps move extra stock and increase profits.

Confronting these common issues helps businesses can prevent lost profits, free up space, and reduce waste.

How Can ReverseLogix RMS Help With Inventory Recovery

ReverseLogix makes inventory recovery easier. With RMS, businesses can track extra stock, automate recovery steps, and speed up decision-making. The system gives real-time updates so businesses know when to resell, repair, or recycle inventory.

ReverseLogix also helps improve your business margin. Its automated tools reduce manual work and improve efficiency. With better tracking, businesses can recover more value and avoid waste.

ReverseLogix’s flexible pricing makes it a great fit for businesses of all sizes. Whether handling returns or surplus inventory, ReverseLogix helps companies recuperate assets and improve profits.