Return-to-vendor returns can be a significant part of retailers’ and vendors’ reverse logistics process, especially as eCommerce shopping drives and an increasing volume of product returns.

When a consumer returns a product, one option for the retailer is to return the product to the original vendor from which the retailer purchased the item. Perhaps the item is defective or broken, or the seller has an agreement in place to use a return to vendor (RTV) arrangement with the retailer.

What does Return to Vendor Mean?

“Return to vendor” is defined as a situation in which a retail company sends returned merchandise back to the vendor that sold it to them.

How does Return to Vendor Work?

Typically, a vendor will have a contract with their dealers that states that dealers are allowed to send back returned items and write off a particular dollar amount of each return, or claim a certain dollar amount each year. There may be a fee associated with RTV orders or the retailer may pay more up-front for items that come with an RTV option.

Situations where RTVs are most common are when an item needs to be repaired, is under warranty and needs a replacement, or when a seasonal item doesn’t sell within a certain timeframe.

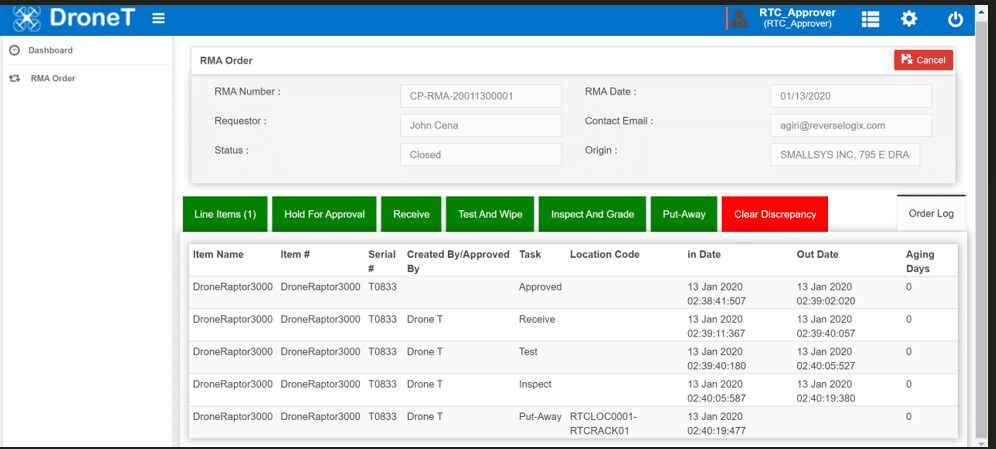

When the time comes, the retailer creates an RTV claim in the returns management system (RMS) – essentially, the claim is a vendor return authorization form (similar to a return authorization form that a consumer fills out when starting a return). Details such as unit cost, requested quantity and restocking fees may be included on the order form.

Example: RTV claim form in the ReverseLogix returns management system

As the sustainability impact of product returns becomes more apparent, vendors may incentivize their network to avoid returns. For example, a vendor may authorize its dealer network to give a discount on an appliance that has a minor cosmetic problem, like a dent. An RMS can facilitate and track these types of return avoidance scenarios.

What is RTV Tracking?

Once an RTV claim is submitted through the RMS portal, the retailer can track the status of it within the same returns management system.

On the supplier side, the RMS provides data and analytics for RTV claims by dealer and overall. With metrics such as claim fees, product and policy validations, shipping costs, and refunds broken down in myriad ways, the vendor can track and manage RTV processes to look for outliers and ensure they’re not incurring fraudulent or unnecessary costs.

Why is RTV Important to Businesses?

RTV is an option for B2C retailers and B2B sellers like manufacturers. For seasonal products, RTV gives the sellers peace of mind that they won’t be left with unwanted products that have to be deeply discounted, take up shelf or storage space, or be landfilled.

For RTV products that are returned to the supplier for repairs, an RTV option is a way to deliver good customer service by standing behind your products and ensuring that if something is not right the first time, it will be fixed.

Why RTV Could be Costly for your Business

As mentioned above, retailers typically pay more for RTV items, either in the initial cost or in RTV fees and shipping fees. That’s why it’s important for retailers with RTV agreements to track and manage them – otherwise, they could cost you a lot more than you think. Here are some examples:

- Time – every step of a reverse logistics process takes time, and the more time that products spend in transit between consumers, retailers, and vendors, the less likely you can resell them for a profit. It’s critical that you can track RTV and use data to guide decisions on when it’s the best choice.

- Fees – many RTV policies can cost you because the vendor will charge a restocking fee. In some cases they will also charge return shipping costs, which could add up if you have a significant amount of product going back to vendors.

- Customer frustration – vendor return strategies may seem like the best idea to avoid handling returns on your own, but the longer it takes for a customer to get their replacement or refund, the more likely they will get frustrated. Most of the time they will blame you as the retailer and choose to take their business elsewhere.

How Retailers can Build a More Robust RTV Strategy

RTV can be costly and have drawbacks if it’s not executed well, but having the right reverse logistics software can help you manage and streamline the entire process. The following are some key technology features that will make RTV easier for you, your customers, and more cost-effective overall.

Consolidation

Shipping individual items back to a vendor return can be very costly, and those shipping costs will add up on your expense sheet. But software can help you consolidate products from various categories and locations together into a larger shipment that is more cost-effective. You save money on freight and shipping charges, and you don’t have to hold on to unwanted inventory.

Inspection & Grading

Marking each returned item with its condition, value, and status helps you track and manage the things that should be sent back to the vendor. Without this level of tracking you could end up sending things back to the vendor that they won’t accept, which (again) adds to your costs. Customizable grading levels and automated tracking can expedite your process.

Contract Terms

If your OEM vendor return contract specifies that only a certain percentage of goods can be returned, the RMS software will track your progress toward that maximum amount. This will help prevent wasted shipments that the vendor won’t accept after you reach your contract terms.

Managing the RTV Supply Chain with a Returns Management System

Return to vendor can be a more complicated and costly aspect of your reverse logistics operations, so it’s important to have 1) the right technology in place to make RTV as efficient as possible and 2) be able to gather data on your RTV claims so you’re not flushing money or wasted products down the drain.

A returns management system (RMS) for retailers, manufacturers, 3PLs and eCommerce companies will be critical for managing RTV claims. An RMS is the only type of software that addresses the full lifecycle of returns management, making it an end-to-end solution that gives you visibility and data into RTV claims.

RTV Vendor Examples

If you are a vendor that accepts RTV returns from your network, a returns management system will give you visibility into incoming items: Where are they coming from? Which partners are sending them in? Is the item arriving under warranty? Is the product returnable based on contract policy or limits? Without an RMS, a vendor would receive “blind returns” – items coming in with no warning or even potentially receiving products that are not even theirs.

Here’s an example: The laptop that you just purchased isn’t working correctly. You bring it back to the big box retailer, who then returns the laptop to the OEM vendor for repair (Dell, Acer, HP, etc.). If the retailer and the vendor have an RTV agreement, then the claim, tracking, and communications will all be handled in the RMS. Because the vendor has given its dealer network a portal into its RMS, all types of returns (not just RTVs) can be handled in one, centralized system for better efficiency, management and visibility.

The RTV supply chain is just one component of reverse logistics, and a holistic view of operations is needed in order to optimize it. To learn more, get our reverse logistics guide or view our pricing plans.