Reverse Logistics Guide: Definition, Challenges, Strategy

Table of Contents

Until recently, most people (and news media) didn’t spend a second thinking about supply chains – the processes and people that it takes to move an item from production into our hands.

But the pandemic and subsequent world events have changed that: Products and parts are scarce or are delayed, and the supply chain has become top of mind for many consumers and companies, whether they are trying to source a new dishwasher or microchip.

This increased attention, and our personal experiences with it, make it important to understand the many parts that make up the supply chain and the logistics of it; especially the term “reverse logistics.”

In this article, we’ll discuss what reverse logistics is, its role in the supply chain, reverse logistics examples, and how it impacts companies and consumers.

What is Reverse Logistics?

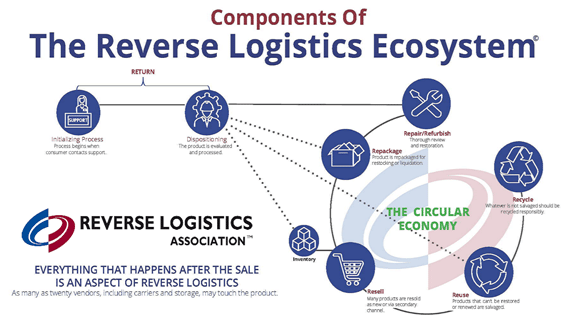

Reverse logistics refers to the processes that happen when a product is returned to a seller or manufacturer. Whether the purchaser is a consumer or a company, the returned product initiates a flow of tasks that must be efficiently orchestrated in order to process the return, give the customer a credit or refund, and then resell, re-use or dispose of the product responsibly.

When is Reverse Logistics Used?

Whenever an item or product is returned to a company, reverse logistics processes are needed to move that product. The return could happen in person at a physical store, through the mail, or at a third-party location.

Differences between Forward Logistics and Reverse Logistics

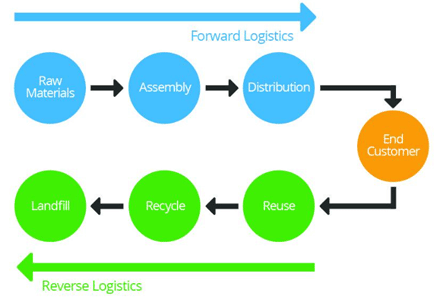

Forward logistics are the processes that are required to get a product to a customer. It’s everything in the supply chain that’s involved in storing or moving materials and goods forward to the buyer.

Reverse logistics is the work that happens to get the returned product back from the customer. Then, the item must be processed, the money refunded or credited, and the item dispositioned (resold, recycled, repaired, landfilled, etc.).

What are the Steps of Reverse Logistics?

The steps of reverse logistics cover all aspects of the returned item’s journey.

- The customer initiates the return, following the seller’s requirements for mailing or physically returning the item to the seller or manufacturer.

- The item must be transported to a returns processing facility.

- The item is inspected, cleaned or repaired if necessary, and then re-sold, recycled, re-used or landfilled.

- The customer is refunded the cost of the item or credited.

What are Examples of Reverse Logistics?

As mentioned, reverse logistics cover all facets of a product’s return journey. One reverse logistics example is when a customer initiates a return and completes a return materials authorization (RMA) – also called a return merchandise authorization.

Example 1:

RMA processes can vary: for expensive items, a company may require a formal document to be filled out with detailed reasoning for the return. For B2C customers returning something inexpensive, like a shirt, the RMA process could be as fast and easy as clicking on an item image in a web portal.

Example 2:

Another example of reverse logistics is the processes that need to happen to prepare the returned item to be resold. If the item is a piece of clothing, it might be wrinkled or returned in a customer’s packaging. Employees at the distribution center or warehouse may have to inspect, clean, and repackage the shirt in a professional way.

With so many items and rules that go into reverse logistics, the most forward-thinking companies rely on a returns management system to standardize workflows and keep everyone working efficiently.

Reverse Logistics Processes

Improving and optimizing reverse logistics processes can be overwhelming, and many supply chain or logistics leaders aren’t sure where to start. Here are the top three areas we recommend targeting when optimizing reverse logistics and product returns:

- Self-service customer tools

- Returns processing

- A single view of the returns process

What are the Five Rs of Reverse Logistics?

If you are a company looking to optimize your product returns processes, you may be wondering which areas to tackle first. Our article on the The Five Rs of Returns Management covers the five foundational components:

- Returns

- Recalls

- Recycling

- Repackaging

- Repairs

What is Reverse Logistics in the Supply Chain?

The terms “supply chain” and “logistics” are sometimes used interchangeably, although that isn’t technically correct.

The supply chain is the entire flow of materials and products, from start to finish. Logistics are one part of the supply chain, referring to the work of storing or moving goods. Reverse logistics are just one component of logistics; they’re the processes and work needed to get a product back to the seller or manufacturer, and properly re-used, recycled or disposed.

Challenges of Reverse Logistics

For years, the software industry focused on providing solutions that helped enterprise companies optimize forward logistics.

Warehousing, transportation and inventory management are all essential supply chain steps that rely on technology to operate efficiently, accurately and cost-effectively. These parts of the supply chain can be true competitive differentiators.

But as the rate of eCommerce shopping increased by double-digits year after year (in both B2C and B2B industries), the volume of product returns is skyrocketing. Suddenly, companies are faced with up to 30% of products coming back in! This has led to enormous challenges:

- Significant warehousing and storage costs

- Inconsistent returns management due to workforce constraints

- Lack of process or policy standardization, which drives up cost

- Increased emissions, packaging and waste

The good news is that supply chain software is finally addressing the needs of reverse logistics. With purpose-built solutions for industries like retail, eCommerce, manufacturing and 3PLs, reverse logistics can be more efficient, faster, less costly, and support a positive customer experience that keeps them coming back.

What are the Benefits of Reverse Logistics Software?

The increasing volumes of product returns make it nearly impossible to manage them efficiently with just spreadsheets and disconnected processes.

- The average rate of returns for online purchases is 20.8% (National Retail Federation)

- Up to 30% of B2B sales may be returned (Forrester)

- For every $100 in returned merchandise accepted, companies lose $10.30 to fraud (McKinsey)

- In a ReverseLogix survey conducted with Lead to Market, 80% of respondents said product return costs are “significant to severe.”

To minimize the challenges of increasing return volumes, keep costs low and improve the customer experience, B2C and B2B companies should implement reverse logistics software.

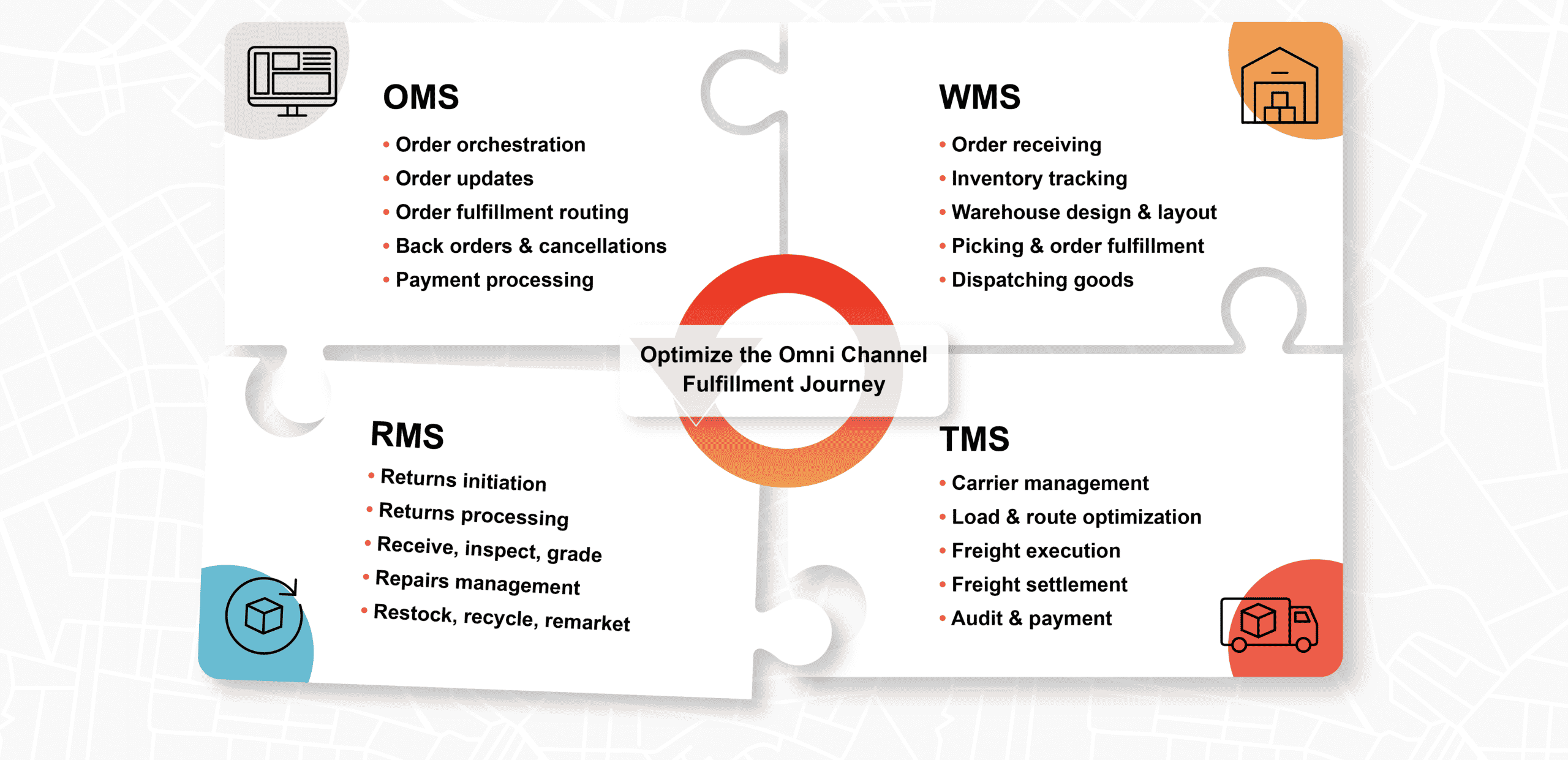

How Reverse Logistics Software can Help your Business

A returns management system (RMS) is the most comprehensive reverse logistics software solution; it integrates and orchestrates the entire returns process, from end to end. Starting with the customer RMA and ending with dispositioning, refund or credit, an RMS ensures everyone is working efficiently and in coordination.

With its ability to integrate with other supply chain management software, it gathers, analyzes and presents returns data and insights so you can better understand the cost, labor and time that goes into returns processing – and how to make improvements. An RMS is the final piece of the supply chain software puzzle.

Reverse logistics and product returns should be automated and straightforward. With software purpose-built for your industry, you can unlock new opportunities for automation, lower costs, improved margins, and strengthen your loyal customer base.

Automated Operations

Reverse logistics software automates returns processes and guides employees on policies and rules so that you have a standard, consistent returns management approach at every store location, warehouse or even 3PL partner.

One of the reasons we chose ReverseLogix was because we could use it in many of our facilities, whether that was with our 3PL partner, in our own warehouses, and potentially in other countries.

Director of Distribution Operations, Global Retailer

Starting with a branded online portal that facilitates quick and easy returns for B2C or B2B customers, reverse logistics software can help your teams automatically approve straightforward returns based on your rules, while automating even the most complicated returns process enforcement.

Companies can receive, inspect, grade and put away returns with no manual work required to log items into the system. Customers receive automatic notifications and status updates that help reduce customer service calls and emails.

Whether you have one store or a global vendor or partner network, automation helps ensure your policies are properly and accurately enforced throughout the returns ecosystem.

Reduced Costs and Improved Margin

Across companies and across industries, product returns are costly. And yet, few companies know their exact cost for managing returns, or what they should do to lower costs!

Fewer than one-third of retailers state that they have visibility of all related returns management costs when it comes to loss in inventory value in storage.

Gartner

A recent study by ReverseLogix, conducted with Lead to Market, reported that 80% of retailers interviewed said the costs of managing their product returns are “significant to severe.”

Those costs include warehousing and equipment, transportation to move returned goods to a central warehouse or store, labor costs for managing the return, and environmental costs associated with recycling or landfilling.

Reverse logistics software delivers the data you need to pinpoint inefficiencies and excess costs, while at the same time driving automation and efficiency. The right technology will have a significant impact on costs in these supply chain areas:

- Automating workflows and processes

- Identifying fraudulent returns

- Providing detailed data and insights so you can proactively address issues

Returns technology takes the guesswork out of managing your returns, empowering your labor force to work more efficiently and empowering managers with reporting data to catch issues or highlight improvements.

Improved Customer Experience and Satisfaction

Easier returns make for happier customers. Two-thirds of buyers check a company’s returns policy before purchasing, so it’s important to have an easy-to-understand policy, clear instructions for making the return, and a fast experience. Understanding post-purchase behavior and providing proper post-purchase messaging can help improve a customer’s experience with returns.

Improved Customer Retention

Providing a fast and easy returns experience is important for all industries, not just retailers. As eCommerce purchases increase – especially in the B2B category – a smooth reverse logistics process is important for retaining customers and protecting your bottom line.

As this article in Logistics Management highlights:

As we see more convergence around serving each unique customer’s needs, reverse logistics will become a standard capability that all companies will need to factor into the supply chain operating models.

Reverse logistics software should offer ways to make your customers’ lives easier, not just address back-end processes. These could include customer-centric features like a branded B2C or B2B portal for quick self-service returns, automatic notifications that keep customers informed of the return status, and customizable policies that automatically approve returns and refunds from known, reliable customers.

A positive returns experience will make or break a customer’s impression of your company, and modern reverse logistics technology can help you ensure that the customer-facing experience is just as easy and efficient as your behind-the-scenes tasks.

Loss Reduction

Without consistent policies and workflows in place, managed by reverse logistics software, returns will quickly drive up costs for both B2C and B2B sellers. Research has found that the cost of managing a return is about 17% of the prime cost, while others estimate the cost to be as high as 30%.

Fraud prevention is another way to reduce loss. Industries lose billions of dollars a year to return fraud: The National Retail Federation found that 10.6% of returns in 2021 were fraudulent, and pymnts.com reported that 30% of B2B businesses lose 3.5% or more of their annual sale revenues to fraud.

Returns technology can reduce return fraud by ensuring employees are inspecting and managing returns accurately. Go here to learn more about preventing returns fraud.

Waste Reduction and Improved Sustainability

The volume and waste of product returns has huge impacts on the environment and can prevent companies from meeting their sustainability goals. Transportation emissions, packaging waste, and landfilling all increase if returns aren’t handled deliberately and strategically.

Reverse logistics software transforms sluggish, wasteful supply chains into processes that support bold sustainability goals. By unlocking new data and insights about your return trends and operations, you can minimize returns before they happen, identify resale and repair priorities, facility re-sale opportunities, minimize waste and more.

On-Demand Tracking and Analytics

A significant reason why most companies have inefficient and costly reverse logistics is because they don’t have the data to improve operations: If you don’t know where the problems are, you can’t fix them.

Reverse logistics software breaks open the black box of data by gathering and delivering real-time returns tracking and analytics. Companies get total visibility into the returns journey to pinpoint inefficiencies, take action on cost-saving or sustainability priorities, and reduce complexity.

What Industries use Reverse Logistics?

Any industry that sells any product will rely on reverse logistics in some way, shape or form. Although retail or eCommerce returns come to mind for most people, the B2B space is reacting to big increases in online purchases and a subsequent increase in returns.

In 2022, 89% of B2B buyers say they have made an online purchase since March 2020… Among those buyers, half (49%) plan to make over 50% of purchases for their company this year online, and another quarter (27%) plan to make between 26% and 50% of their purchases online this year…

Digital Commerce 360

Let’s look at a few of the most common industries that rely on reverse logistics, and why returns management technology is so important for customer satisfaction, lowering cost and streamlining operations.

eCommerce

Perhaps more than any other industry (and thanks to sites like Amazon for setting the standard), eCommerce customers expect returns to be fast, easy, and to be refunded or credited ASAP.

Returns management software that’s built to handle the complexities of eCommerce returns management can create a competitive advantage for your company, allowing you to maximize repurchase and lower the cost of handling returns.

Third-party Logistics Businesses (3PL)

Managing returns can be exceptionally complicated for 3PLs, but returns technology has changed that.

3PLs can configure workflows and requirements for diverse customers across warehouses and shipping locations – and get total visibility into all of it. A growing number of 3PLs are offering reverse logistics services and third-party logistics solutions, helping them stand out in a commoditized industry. They’re providing a new service that few customers have mastered themselves – but are happy to pay for!

Manufacturers

Returns management technology enables manufacturers to process returns, return-to-vendor items, perform repairs and refurbishments, and complete put-aways.

Here at ReverseLogix, our manufacturing customers have saved millions of dollars with our returns management system by avoiding over-crediting and vendor policy abuse.

Manufacturers have a huge opportunity to grow customer loyalty with a frictionless returns experience – rare in the world of complicated B2B returns.

Reverse logistics software also helps alleviate tight labor markets and worker shortages – challenges that can be especially acute for manufacturers. Leveraging returns technology will have an immediate impact on the efficiency and effectiveness of a labor force, getting more out of what you already have.

Retail

Whether you have multiple stores or a blend of brick-and-mortar and eCommerce, reverse logistics technology helps manage the entire returns journey: Tracking and managing returns, visibility into inventory rotations, and better data so you can minimize loss – like getting seasonal items back into rotation in the right markets.

By addressing retail returns management with purpose-built technology, you can give customers a flexible returns experience (like buy-online-return-in-store) and even incentivize them to return items to locations that are most efficient and cost-effective for your operations.

How to Improve your Reverse Logistics Process

Improving reverse logistics processes in your organization requires purpose-built technology that addresses returns challenges comprehensively and with a data-driven approach. However, it also requires strong leadership and coordination among several functional areas.

Each organization will have slightly different priorities for improving reverse logistics based on what they are already doing well, as well as the greater business goals, and the return rates. But here are a few common areas to consider…

- Evaluate relevant policies and agreements

- For better collaboration with suppliers, consider a reverse logistics software platform that can be implemented across your network

- Use data to optimize processes

- Product tracking

- Centralized return centers (such as microfulfillment centers for product returns)

- Automation

As this article from Logistics Management points out:

…without true collaboration between all the functional areas involved, companies find themselves faced with siloed, ad hoc decision making and a limited ability to optimize the economics of reverse logistics and the impact for the end-to-end business.

Conclusion

The ability to efficiently manage product returns is becoming a higher priority for the world’s most forward-thinking organizations. As B2B eCommerce purchases increase, B2B product returns will increase hand-in-hand.

As B2C online buying continues increasing, consumers’ expectations for fast and easy returns – not to mention the practice of buying several items colors or sizes with the expectation of returning most of them – will only turn up the pressure on reverse logistics operations.

If not managed efficiently, reverse logistics can become a costly area for a company. Without the right data and analytics, reverse logistics will be a black box of issues, with no clear insight into where the problems are or how to address them.

Reverse logistics software, purpose-built to handle the complexities of your industry, is the last piece of the supply chain software puzzle, fully maximizing the value of returns and of your hard-working labor force. But don’t take out word for it – discover how ReverseLogix reverse logistics offerings stack up to Chat GPT’s information!